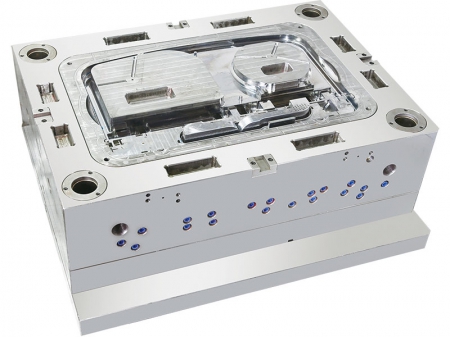

Plastic Engineer Mold (Pipe Fitting Molds)

Not only do we manufacture plastic injection molds for automobiles and motorcycles, but we also manufacture pipe fitting molds. To help reduce expenses the pipe fitting manufacturers spend on molds, we continuously improve upon the structure of the plastic pipe fitting molds.

Quality Control

1. We do not use chrome plated steel materials, 3Cr.13 stainless steel or any other stainless steel materials to make our plastic injection mold cavities and cores. Steel materials that we use for making cold cavities and cores are processed with quench hardening to achieve a hardness of HRC46-50.

2. Our company has special mold manufacturing schematics to make sure that outer and inner diameters of the mold cavities and cores conform to customer requirements.

Due to these strict quality control features, the plastic pipe fitting produced using our plastic injection molds are popular with pipe fitting users.

We welcome pipe fitting manufacturers to contact us, and we believe that we can provide ideal pipe fitting mold solutions to fit your needs.

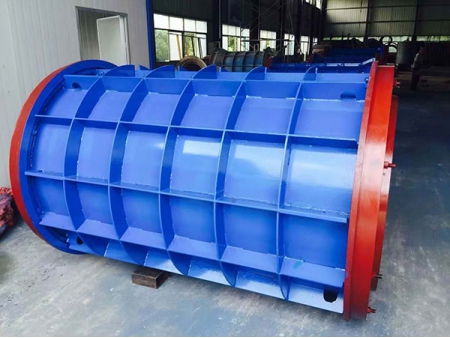

Existing Products: Throughout the years, we have mainly produced the following plastic injection molds for pipe fittings:

1. PVC pipe fitting mold (Mold for PVC elbow, PVC oblique cross, UPVC pipe fitting and CPVC pipe fitting)

2. PE pipe fitting mold (Mold for PE check valve)

3. PP pipe fitting mold (Mold for PP catch basin pipe fitting and PP cross pipe fitting)

4. PPR pipe fitting mold (Mold for PPR bridge elbow)

5. PPSU pipe fitting mold (Mold for PPSU pipe clamp and other PPSU pipe fittings)

6. PPI pipe fitting mold

7. PE-X pipe fitting mold

8. PB pipe fitting mold

9. ABS pipe fitting mold

-

U-shaped elbow mold -

90° elbow mold -

Oblique l tee mold -

Ball valve mold -

16-cavity mold for tee -

Flare tee mold -

Tee mold -

Three-way elbow mold -

Four-way elbow mold -

Elbow mold -

Oblique flare tee mold -

Oblique cross mold -

Irregular shape tee mold