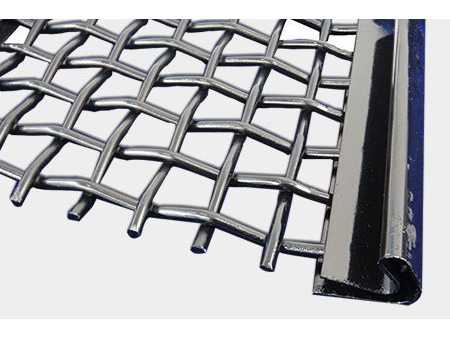

Filtration Wire Mesh

Filtration Wire Mesh

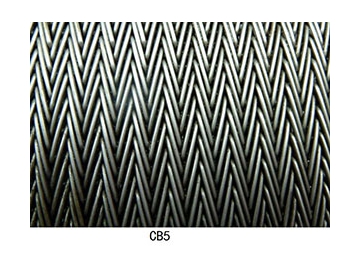

Our knitting process creates a material that, when layered, spiral wound or compressed, produces a tortuouspath for highly effective particle capture. In fact, by careful selection ofwire type, diameter, density and shape, it is possible to overcome challengingfiltration problems that other materials find difficult to handle.

Filtration Wire Mesh Comes In a Variety of Forms

The knitted mesh filter, or also filtration wire mesh, can be supplied in anymetallic or non-metallic material that can be drawn into a filament. It isavailable in a wide variety of forms including mesh rolls, circular andrectangular pads, complete filters and compressed elements. Where necessary,metal alloys or plastics can be provided that are highly resistant to corrosionand can withstand temperatures in excess of 1000°C.

Thermal And Shock Resistance In Filtration Wire Mesh

The flexibility of filtration wire mesh enables it towithstand thermal shock and vibration without breaking up. This provides considerableadvantages over paper and sintered filters and also permits a tightinterference fit within housings without machining to close tolerances. Low-cost tooling enables theproduction of compressed elements that give a minimal pressure drop and also excellentrecovery characteristics after compression.

Yanda-Guohai is a