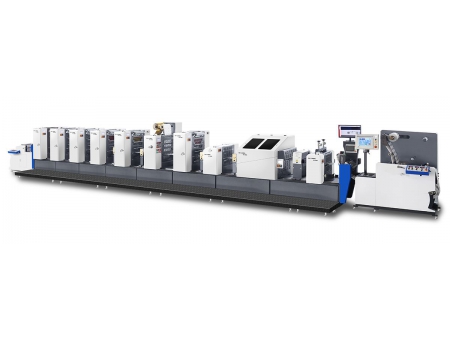

8-Color Intermittent Letterpress High Speed Label Printing Machine

8-Color Intermittent Letterpress High Speed Label Printing Machine,SUPER-320

The 8-color intermittent letterpress high speed label printing machine applies to the printing of coated paper stickers, aluminum foil paper stickers, thermal paper, as well as PE, PVC and PP stickers. It adopts servo control system and the servo motor that drives each printing unit can be precisely controlled, thus achieving optimal control of the whole equipment. Due to the adoption of reciprocating paper feeding method, the printing can be completed by just one plate cylinder. The maximum printing speed reaches 250r/min and the resolution is 175LPI or more.

Specifications

Max. Width of the Material | 310mm |

Max. Printing Width | 290mm |

Printing Length Range | 50-260mm |

Printing Color | 2-8 colors |

Thickness of the Printed Material | 0.1-0.3mm |

Machine Speed | 30-250r/min |

Max. Diameter of Unwinding | 700mm |

Max. Diameter of Winding | 700mm |

Host Power | 17.3kw (Not including UV system) |

Host Power Supply | 380V/AC Three-phase, 50/60Hz, 50A, 17.3KVA |

Overall Dimensions | 6800×1600×1400mm |

Weight | 6000kg /6 colors |

Note: 1.Machine speed varies with the change of the printing length. | |

Optimized ink roll configuration and speed are employed, which prevents ink streak and ghosting, thus improving printing effect. Ink supply changes proportionally with the machine speed so as to achieve better printing result. Machine faults are displayed on the computer screen, so users can see the trouble location directly, which accelerates repairing. In addition, our product can complete unwinding, varnishing, die cutting, waste discharging, winding and many other processes.

The SUPER-320 intermittent letterpress high speed label printing machine can be used to print adhesive labels for packaging boxes, bottles or bags in cosmetic, food and many other industries. It uses cast iron as the raw material which has been chrome plated to resist rust, so it has a long lifespan. The carefully chosen gear, roller and other accessories help to produce accurate printing effect. The equipped UV drying device enables the ink to solidify quickly, thus solving the problem of easy falling off of the ink on the finished product. With the size of 6800×1600×

Optional Devices

1. Hob-die-cutting Device (Magnetic drum)

2. UV Drying Device (Width of the light box is within

3. UV Varnishing Device

4. CCD Camera

Servo Control System

Independent Motor Inking System

Vacuum Paper Feeding System

Central Control System

Superior Ink Transfer System (ZONTEN Patent)

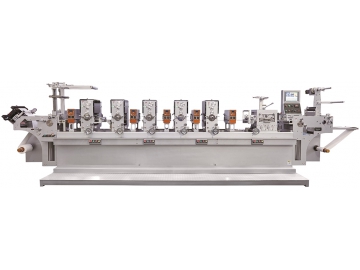

CS-300-5C Intermittent Rotary Letterpress (Label Printing, Vision Inspection, Backside Printing)

labelprinter-inc.com

CS-300-5C Intermittent Rotary Letterpress (Label Printing, Vision Inspection, Backside Printing)

labelprinter-inc.com

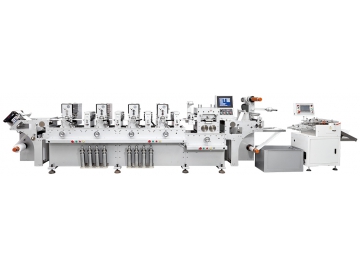

CS-220-4C MINI Intermittent Rotary Letterpress (Compact Design, Label Printing)

labelprinter-inc.com

CS-220-4C MINI Intermittent Rotary Letterpress (Compact Design, Label Printing)

labelprinter-inc.com