Vacuum Coating Machine for Automobile Headlight Housing

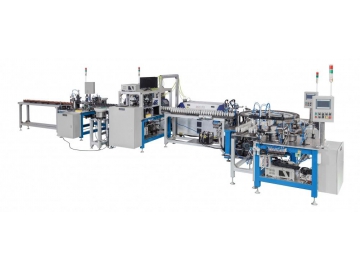

Using electric resistance heating, the vacuum coating machine vaporizes the aluminum target and deposits ionized aluminum onto the surface of your headlight housing as well as safety reflectors. The vacuum metallizer used for this purpose is comprised of the vacuum chamber, pumping system, rotary substrate, aluminum target, gas supply system, and electrical control. Built with mature technology, BITE vacuum coater is easy to operate, efficient to run, and can fast lay coatings on complex part geometries.

Applications of Vacuum Coating Machine

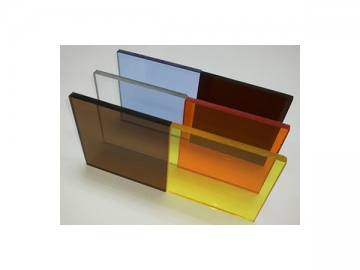

The vacuum coating equipment is suitable for use in luminaire, decorative materials and safety reflectors.

Features of Vacuum Coating Machine

1. The vacuum coating machine automatically and reliably completes the entire coating process, including vacuum pumping, sputter cleaning, aluminum coating, protective coating, and gas discharge.

2. The vacuum chamber is equipped with 2 doors. Each door is fitted with 6 or 8 rotary substrate holders and the cathode for evaporation. The deposition process is carried out separately within the two doors. While the substrate is being coated inside one door, operators can load or unload finished substrate inside the other.

3. Concurrent ion beam bombardment system is available upon your request, able to apply a protective coating (SiOx) to the component waiting to be coated.

Recommended Model