Vacuum Coating Machine for Door Handle

The spider-webbed cracking or flaking on your door handle might be the least you want and reflects the poor coating quality. With BITE vacuum coating machine, door handle manufacturers can have one less thing to worry about. The vacuum metallizer quickly coats your door handle with a shiny layer of coating typically comprised of metals or metal compounds.

Using touch screen and PLC to reliably and automatically complete the coating process, operators can have more to expect on BITE vacuum coater, including the vacuum gauge, flow rate control, bias voltage power supply, cathodic arc power source (with voltage converter), side-mounted heating tubes, and PID temperature controller.

Because BITE vacuum coating process uses an advanced physical vapor deposition method, it does not generate any emissions and has received increased uses in recent years.

Materials Applied

TiN, TiC, ZrN, CrN, Ti, Ni, Cr, Cu, Silver and gold. BITE vacuum coating system enables a fast deposition rate, high ionization degree, and a variety of colors to be deposited. The resultant coating is wear-resistant and lasts for years to come.

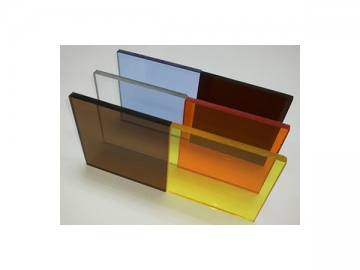

Colors Applied

BITE vacuum coater can put many colors on your door handle, including gold, coffee, brass, grey, black, blue, rose, and rainbow color. Excellent adhesion, mechanical bond, repeatability, and color uniformity are major benefits of this physical vapor deposition process.

Recommended Models