Capability

Since our founding in 2008, X-RHEA has accumulated significant experience in the customization and production of luxury packaging products. We offer customers a wide selection of raw materials and multiple processing techniques to satisfy all of the custom requirements put forth by clients.

We own and operate two well-equipped factories, including two workshops for paper products, one for leather products, and one for bags. These workshops are equipped with a series of manufacturing and processing machines, including fully automatic hot stamping machines, fully automatic die cutting machines, rigid box making machines, and case making machines. Multiple semi-automatic and fully automatic production lines allow us to supply 5,000-10,000 finished products per day.

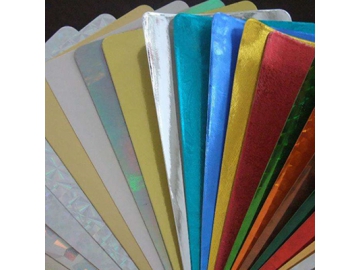

Here at X-RHEA, we use a wide variety of raw and auxiliary materials such as paper, leather, fabric, MDF (Medium Density Fiberboard), and foam.

Storing them in our large warehouse, most raw materials are purchased in accordance with the order quantity of customers. We do however maintain a stock of commonly used raw materials in case of emergency. Some special raw materials are stored in protective plastic bags. The warehouse is large and safe, allowing us to store large amounts of raw materials without affecting quality or productivity.

Cardboard

Cardboard  Coated paper

Coated paper  Leather

Leather  Fabric

Fabric  Fabric, MDF (Medium Density Fiberboard)

Fabric, MDF (Medium Density Fiberboard)  Foam

Foam

Our comprehensive manufacturing and processing equipment allows us to complete the whole production process ranging from raw material handling to surface treatment. Therefore, we can provide customers with an outstanding selection of boxes, organizers, bags, and printed products.

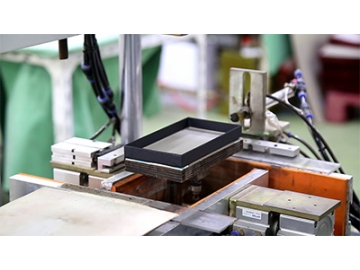

Equipped with die cutting machines, case making machines, cardboard slotting machines and automatic gluing machines, our factories have everything needed for the production of custom boxes

The semi-automatic and fully automatic die cutting machines can cut custom shapes out of various raw materials.

The semi-automatic and fully automatic die cutting machines can cut custom shapes out of various raw materials.  The fully automatic case making machines feature an output capacity of 6,000-8,000 pcs per day.

The fully automatic case making machines feature an output capacity of 6,000-8,000 pcs per day. The production capacity of our fully automatic rigid box making machines reaches 6,000-8,000 pcs per day.

The production capacity of our fully automatic rigid box making machines reaches 6,000-8,000 pcs per day.

Outfitted with die cutting machines, sewing machines, fabric cutting machines and leather skiving machines, our factories have everything needed to form all the processes of bag production.

- The workshop for bags is equipped with many sewing machines.

Our factories have everything needed for the production of various printed products.

- The paper cutting machines cut raw materials to make a wide range of product sizes.

- The die cutting machines cut all sorts of raw materials into custom shapes.

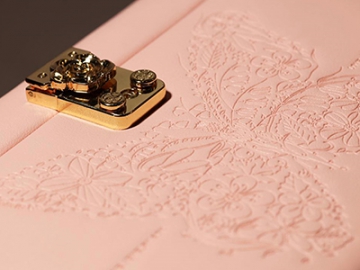

We can provide a variety of surface treatments such as printing, embossing, debossing, and hot stamping. Different surface treatments help us to create custom figures, patterns, and logos on products in line with the requirements put forth by the client.

Printing

Printing  Debossing

Debossing  Hot stamping

Hot stamping

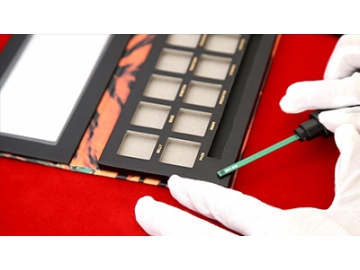

According to the specific requirements of individual products, our quality operators randomly inspect raw materials to guarantee size, thickness, color, and other requirements are met.

In the mass production process, experienced quality operators are assigned to each production line to perform quality inspection for semi-finished products.

Finished products of each project will be inspected fully or randomly. The strict inspection system gives clients 100% certainty of the quality of their products. Any defective finished product will be identified and removed before delivery.