CNC Machining Automotive Shock Absorber, Suspension Parts

Aluminum alloy

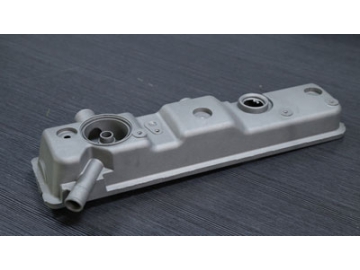

Product name: Cylinder head

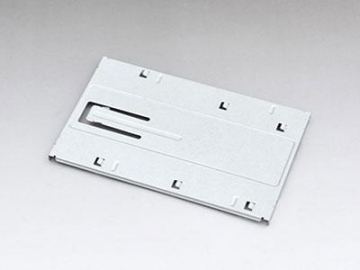

Aluminum alloy

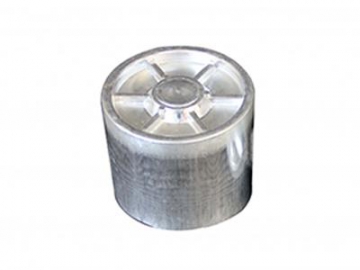

Product name: End bracket

Aluminum alloy

Product name: Cylinder head

What we can do?

The shock absorber is used in automobile, motorcycle and race car suspension systems. It is a key suspension system component to ensure a stable vehicle operation, as it ensures an excellent wheel grip and efficient steering and braking performances in order to improve vehicle safety levels. Asia America offers a variety of shock absorber parts, including cylinder heads, high speed adjusters, bracket reservoirs, guide rings, spring platforms, gas piston set tools, and valve double bleed.

Materials that can be machinedAluminum alloy: AL6061, AL6063, AL6082, AL7075.

Copper alloy: brass, bronze, BeCu, pure copper.

Stainless steel: sus303, sus304, sus316, sus420, sus440c, sus630.

Engineering plastics: PP, PVC, PEEK, PI, POM, PTFE.

- Preform body

- Forging + machining (turning + milling) or complete machine machining (turning + milling)

- Surface treatment

- Packaging and delivery

- Raw material preparation according to customer design drawing requirements.

- Cut the material with the sawing machine. The assembly workpiece adopts custom-built fixture.

- A CNC milling machine is used for rough cutting, and a CNC 4-axis (5 axis) milling machine or CNC turning lathe for machining of related sizes.

- Remove the burr and check the related precision hole, position and size and appearance.

- Conduct surface treatment according to the design drawing requirements. Then re-check the related precision hole, position and size and appearance.