Corrugated Flexible Conduit Workshop

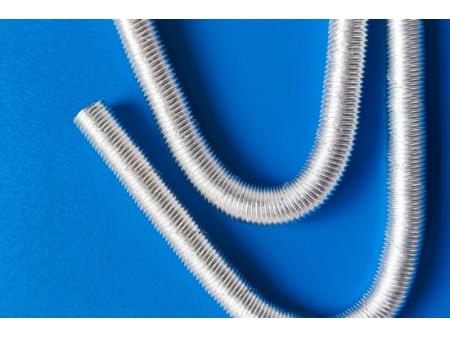

The corrugated flexible conduit workshop has 5 production lines, which can produce both German and Japanese standard corrugated flexible conduits with a total of 21 types, and a monthly output of 1 million meters.

This production workshop is located in Jdd 's Houting factory.

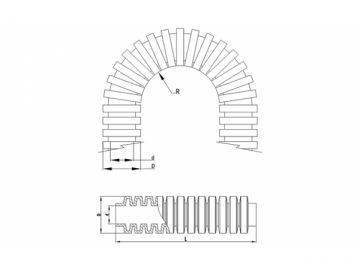

Process and Equipment

Our workshop is completely equipped with an extensive line of equipment that completes the entire production process for corrugated flexible conduits, including mixing, extruding, forming, splitting, winding, cutting, testing and packaging.

- The mixing process uses an electronic scale to weigh the raw materials, master batch, accelerant and other materials according to a certain proportion, and then mixes them using a mixer.

- The product is extruded and formed using hopper plastic dryer, main machine, and traction machine.

- The control panel is used to control the work of the corrugated flexible conduit production line.

- An extruder is used for extruding the corrugated flexible conduit.

- A winding machine can control the size of packing corrugated flexible conduit. Each bundle is 100m long.

- A cutting machine is used for cutting the opening on the product.

The worker is debugging the cutting machine, this machine can cut the product into sections according to a certain size.

The worker is debugging the cutting machine, this machine can cut the product into sections according to a certain size.Related products

Send Message

Most Recent

More

Other Products

Videos