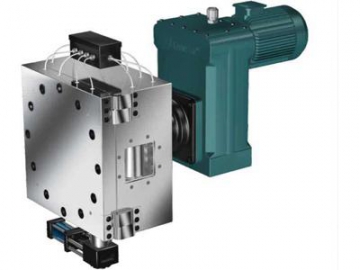

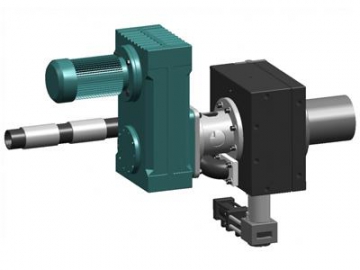

Filtration System Melt Filter for Granule Extruder

- Cooperation time: 2016

- Client: Shanghai Jixiang Building Materials Group

- Requirements: the production cost of the previous granulator production line was too high. A new automatic self-cleaning screen is required to match the extrusion system, cut down the manufacturing costs and improve the market competitiveness.

- Solution: according to the development of plastic filtration industry and customer’s extrusion system, we specifically developed a new product, the LN500 rotary duplex cleaning blade continuous melt filter to match their production line.

- Feedback: after usage, the production efficiency has greatly increased. The quality and performance of the production line also have improved. Jixiang’s requirements and goals have been successfully satisfied and achieved.

- Cooperation time: 2017

- Client: Foshan Kamen Decoration Materials Co., Ltd.

- Requirements: Kamen used to purchase granules to produce plates, which leads to high production cost and low material performance.

- Solution: LEENY provides them with a LN500 duplex cleaning blade continuous melt filter, which directly utilizes broken crumbles, omits granulating procedure and greatly improves material performance and plate quality.

- Feedback: customer has reduced their production cost and energy consumption, improved quality and performance of the products by using our LN500 duplex cleaning blade continuous melt filter.

Related products

Send Message

Most Recent

More

Other Products

Videos