Electronics Manufacturing (hot melt adhesive for wiring and PCB bonding)

Hot melt adhesive pellets and stick are widely used to position, bond and seal electrical components, and in the process of low pressure molding for the protection of electric wires and cables.

The following hot melt adhesives we recommend offer good viscosity and their viscosity will remain unchanged whether in high or low temperature conditions. This significantly reduces the influence of temperature changes resulting from electrical current.

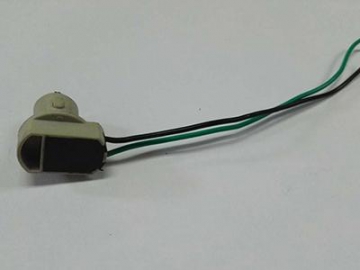

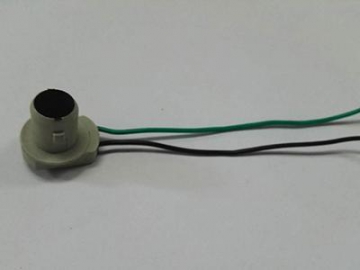

Application- Glue stick and adhesive pellets are used for the bonding and positioning of electric components

- Glue stick and adhesive pellets are used for bonding electric wires

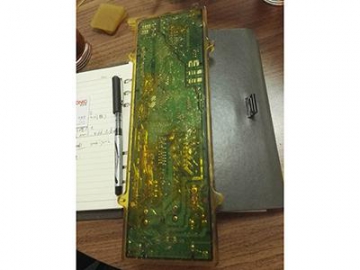

- Adhesive pellets are used for positioning circuit boards

- Moisture curing PUR hot melt adhesive is used for sealing mobile phone frames

- Hot melt adhesive pellets are used to make heat-shrinkable tube liners

- Hot melt glue pellets are used for low pressure molding

| Model | 8620M(low pressure molding) | 8620BM(low pressure molding) | 8640M(heat-shrinkable sleeving) |

| Appearance | Buff, transparent, pellet | Black, non-transparent, pellet | Buff, transparent, pellet |

| Hardness | / | / | 40~50A |

| Viscosity | 2000cps~4800cps/200℃ | 2000cps~4800cps/200℃ | 1300cps~5500cps/200℃ |

| Softening point | 115℃~125℃ | 115℃~125℃ | 140℃~145℃ |

| Operation temperature | 140℃~180℃ | 140℃~180℃ | 140℃~180℃ |

| Glass transition temperature | -40℃ | -40℃ | -40℃ |

| Curing speed | 3s~6s | 3s~6S | 2s~5s |

| Density | 0.95g/cm3 | 0.98g/cm3 | 0.95g/cm3 |

| Acid value | < 6mg(KOH)/g | < 7mg(KOH)/g | < 6mg(KOH)/g |

| Amine value | < 3mg(HCL)/g | < 3mg(HCL)/g | < 6mg(HCL)/g |

| Weight/per | 25kg/sack paper bag | 25kg/sack paper bag | 25kg/sack paper bag |

| Model | 8650BM(low pressure molding) | 8675M | 8675BM(low pressure molding |

| Appearance | Black, non-transparent, pellet | Buff, transparent, pellet | Black, non-transparent, pellet |

| Hardness | 88A | 92A | 92A |

| Viscosity | 2200cps~3500cps/200℃ | 2500cps~4500cps/200℃ | 2500cps~4500cps/200℃ |

| Softening point | 150℃ | 175℃±5℃ | 175℃±5℃ |

| Operation temperature | 180℃~200℃ | 200℃~220℃ | 200℃~220℃ |

| Glass transition temperature | -20℃ | -40℃ | -40℃ |

| Endurable environmental temperature | / | -40℃~150℃ | -40℃~150℃ |

| Curing speed | 1s~3s | 3s~5s | 3s~5s |

| Oxidation resistance | / | 200℃/5h | 200℃/5h |

| Elongation | / | 500%~600% | 500%~600% |

| Shrinkage rate | / | < 1% | < 1% |

| Water absorption | / | < 1% | < 1% |

| Density | 0.98g/cm3 | 0.95g/cm3 | 0.95g/cm3 |

| Acid value | < 2.2mg(KOH)/g | < 6mg(KOH)/g | < 6mg(KOH)/g |

| Amine value | < 6.7mg(HCL)/g | < 3mg(HCL)/g | < 3mg(HCL)/g |

| Weight/per | 25kg/sack paper bag | 25kg/sack paper bag | 25kg/sack paper bag |

| Model | 8121M | 8122M | 8142GM |

| Appearance | Buff, transparent, pellet | Buff, transparent, pellet | Buff, transparent, pellet |

| Hardness | / | / | / |

| Viscosity | 2000cps~4000cps/200℃ | 2000cps~4000cps/200℃ | 2000cps~4000cps/200℃ |

| Softening point | 115℃~125℃ | 115℃~125℃ | 135℃~145℃ |

| Operation temperature | 180℃~200℃ | 170℃~190℃ | 170℃~190℃ |

| Glass transition temperature | -5℃ | -8℃ | -8℃ |

| Curing speed | 4s~8s | 3s~5S | 3s~5s |

| Density | 0.95g/cm3 | 0.95g/cm3 | 0.95g/cm3 |

| Acid value | < 7mg(KOH)/g | < 6mg/g | < 6mg/g |

| Amine value | < 3mg(HCL)/g | < 6mg/g | < 3mg/g |

| Weight/per | 25kg/sack paper bag | 25kg/sack paper bag | 25kg/sack paper bag |

| Model | 8120BN | 8620N | 5003N | 5003NQH |

| Appearance | Black, non-transparent, stick | Yellow, transparent, stick | semi-transparent white glue stick | semi-transparent white glue stick |

| Hardness | / | / | / | / |

| Viscosity | 1800cps~3500cps/200℃ | 2000cps~4500cps/200℃ | 3500cps~4500cps/180℃ | 1500cps~4500cps/180℃ |

| Softening point | 115℃~125℃ | 125℃±5℃ | 75℃~85℃ | 80℃~90℃ |

| Operation temperature | 160℃~190℃ | 180℃~200℃ | 160℃~180℃/150℃~170℃ | 160℃~180℃ |

| Glass transition temperature | 0℃ | -40℃ | -5℃ | -5℃ |

| Curing speed | 3s~5s | 5s~10s | 10s~20s | 8s~15s |

| Density | 0.95g/cm3 | / | 0.92g/cm3 | 0.92g/cm3 |

| Acid value | / | / | / | / |

| Amine value | / | / | / | / |

| Weight/per carton | 25kg/carton | 25kg/carton | 25kg/carton | 25kg/carton |

Related products

Send Message

Most Recent

More

Other Products

Videos