Key Board Screw Driving

Disadvantages of manual screw driving

The key board needs many locking screws, which are usually very tiny and therefore many problems may happen when manually locking screws, like screw slippage, screw missing and low production efficiency. The client wanted to adopt a new automatic screw driving system to replace manual work.

Requirements

- The key board is shown as follows and it needs 15 M2*5 Philip's head screws to fix.

- The high quality of screw driving should be ensured with the defective rate lower than 1‰. The screw surface should remain smooth and unscratched.

OKATA GT-LS501SY automatic screw driving solution

- Features

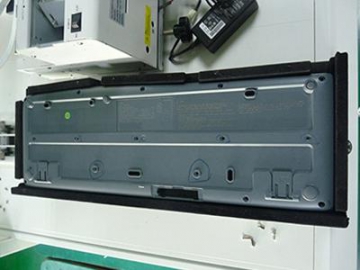

X, Y, Z axis single head double platform auto screw driving machine. PLC control, precise operation, high stability. Double platform allows for simultaneous work of material loading and product handling, which leads to higher production efficiency. - Clamping fixture

The clamping fixture is designed by our professional mechanical engineers on basis of product’s characteristics. - Operations

The screw driving system is fully automatic. The workers only need to put the key boards on the clamping fixture of Y platform and press the start button, then the screw driving machine will handle the products as designed programs.

Picture of automatic screw driving machine

Related products

Send Message

Most Recent

More

Other Products

Videos