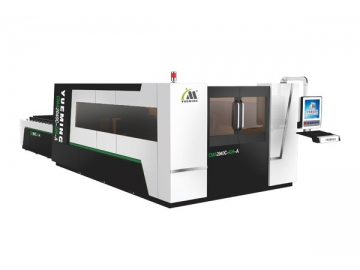

Large Format 3KW IPG Fiber Laser Cutting Machine

Incredibly fast and flexible, the ACCURL Genius 3kw fiber laser cutter is ideal for ultra-high speed cutting of thin sheet materials. It also features the ability to cut a wide range of ferrous and non-ferrous metals, while maintaining low cost operation.

• User friendly FAGOR 8060 CNC control unit.

• Unique features:

-Maximum simultaneous positioning speed: 160m/min.

-Acceleration speed: 25 m/ s2 (2.5G).

-Precision: ± 0.05 mm.

-Energy efficiency: greatly reduced power consumption.

-IPG YLS-3000w Resonator

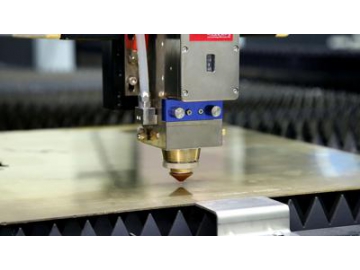

• Advanced PRECITEC cutting head (with air cross blast).

• Fully enclosed to ensure maximum operator protection.

• Effective high to low pressure gas exchange system.

• Automatic time and unit cost calculation function.

• Network connection from external.

• Smoke extraction (included in series models).

• Collection of work pieces and trimmings.

• Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

Introduction:

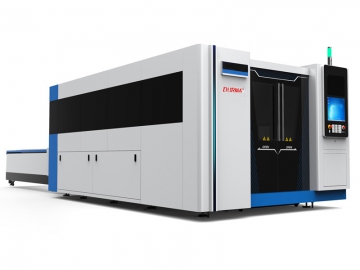

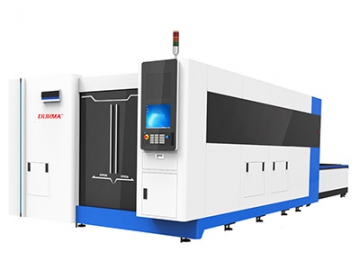

Fiber Laser Cutting Machine with Double Pallet Changer

High Speed Large Format Full Closed Type

Laser Power: 3000 watts

Pallet working table, saving time for material uploading, further improving working efficiency.

Cutting Area: 1500mm×3000mm, 2000mm×4000mm, 2000mm×6000mm

Double gear rack closed-loop system and PMAC Controller (America Delta Tau Systems Inc)

Standard Equipment:

• FAGOR 8060 CNC Controller

• IPG YLS-3000W Ytterbium Laser Resonator

• Automatic Double Pallet Changer(Shuttle Table)

• Precision Rack & Pinion Drive System (Made in Germany)

• Radan or Lantek CAD/CAM system

• Light source

• Chiller

• 3 lower protective lenses

• 3 Ceramic Nozzle Adapters

• Auto-calibrated nozzle system

• Lens with 5.9” Focus Length

• Smart Slag Collection System/ Chip Conveyor

• Fiber Beam Transmission System (Fiber Cable)

• Operates with both N2 and O2 (cutting) gases

• Home Position Alignment System

• Auxiliary Gas Selector

• Auto Reflection Warning

• Working Lights

• 5 Nozzles each of the Following: (1.0mm, 1.2mm,1.5mm, 2.0mm , 2.5mm , 3.0mm)

| Model | ECO-FIBER 3015 / 3KW | |

| CNC Control Unit | FAGOR 8060 CNC System | |

| X axis (Rack & Pinion) | 3000 mm | |

| Y axis (Rack & Pinion) | 1500 mm | |

| Z axis (Ball Screw) | 100 mm | |

| Maximum cutting capacity | Mild steel | 20 mm |

| Stainless steel | 10 mm | |

| Aluminum | 8 mm | |

| Work piece dimensions | 1525 x 3050 mm | |

| Rapid traverse (X and Y axis) | 105 m/min | |

| Acceleration | 2.5G (25m/s2) | |

| Vector speed | 148 m/min | |

| Absolute positioning accuracy | ± 0.08 mm | |

| Repeatability (X and Y axis) | ± 0.03 mm | |

| Max. load capacity | 2450 kg | |

| High Performance CNC System | FAGOR 8060 from Spain Brand | |

| Laser power | IPG YLS-3 kW from Germany | |

| High Performance Servo motor/drive | FAGOR from Spain Brand | |

| Laser Cutting Head | PRECITEC from Germany | |

| Motoreducer | STOBER from Germany | |

- Germany PRECITEC Laser Cutting Head

- IPG YLS-3 kW Laser power from Germany

- STOBER Precision Rack and Pinion Drive System (Made in Germany)

- Linear guide and Rack

- Framework by heat treatment