Melting and Casting Line

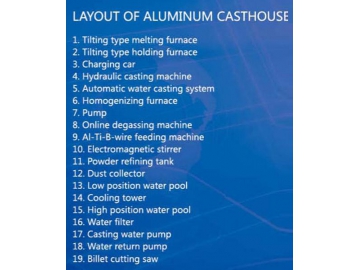

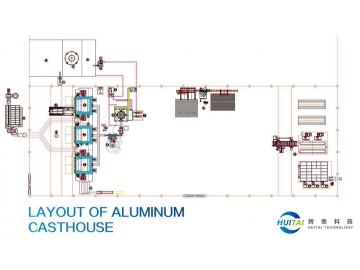

This is a list of supporting equipment required for a complete tilting melting and casting workshop layout, including tilting melting and holding furnace, charging machine for melting furnace, hydraulic casting machine, automatic casting system, homogenizing furnace, submersible pump, online degasser, wire feeder, stirrer, refining tank, dust removal equipment, low level water tank, cooling tower, high level water tank, water filter, casting water pump, return water pump, sawing machine.

Production line that has the lowest costThe main advantage of this production line is the relatively lower cost as compared to the others. It consists of 5-tons fixed melting and holding furnace, melting furnace brick liner, hydraulic casting machine, φ120*6200mm 28 hot top casting machine platform, refining tank, launder, filtration tank and dust removal equipment. It is suitable for small scale aluminum smelting and holding workshop. Besides, it has the ability to cast up to 3-4 furnace molten aluminum and the production per day is 15-20 tons of aluminum rods.

Production line with highest efficiencyThis production line has high efficiency in manufacturing the aluminum rods. It consists of 25-tons tilting aluminum melting furnace, charging machine, 25-tons electromagnetic stirrer, 25-tons hydraulic flap gate casting machine, φ127*6200mm*120 hot top casting platform, refining tank, launder, filtration tank, cooling tower, return water pump and so on. It is applicable in aluminum production factory which require high efficiency and large production. It has advantages include short charging period, small energy consumption, uniform melting of molten aluminum, etc. It can carry out production of 75-100 tons of aluminum rods per day.

Production line with the best quality of aluminum rodsThe main advantage of this production line is manufacturing high quality aluminum rods. It consists of 25-tons aluminum melting furnace, charging machine, 25-tons electromagnetic stirrer, 25-tons hydraulic flap gate casting machine, φ178*6200mm*60 hot top casting platform, launder, feeder, online degasser, electric heat preservation tank, nitrogen generator, cooling tower, electromagnetic stirrer, homogenizing furnace, cooling room and so on. It has features include short charging period, small energy consumption, uniform melting of molten aluminum and high production efficiency of aluminum rods. With the addition of homogenizing furnace, the aluminum rods have uniform composition.