Minerals need to be ground into a powder before they can be used in fields that utilize chemicals, rubber and ceramics. Nano-scale ultra-fine mineral powders have extensive uses, ensuring a high product economic value. As an example, ultra-fine kaolin powder is not only used to produce high-grade coated paper but is also added to a variety of plastic products to improve the finish, elasticity, toughness, and anti-aging ability. Ultrafine talcum powder improves coating smoothness and replaces expensive titanium dioxide during latex paint production. It is also used in the production of a variety of moisturizers and creams. Ultra-fine diatomaceous earth powder is often used to produce non-toxic biological pesticides.

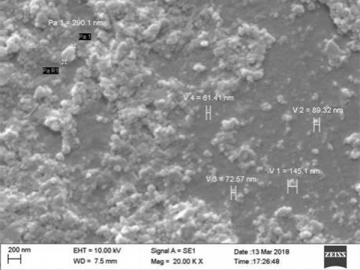

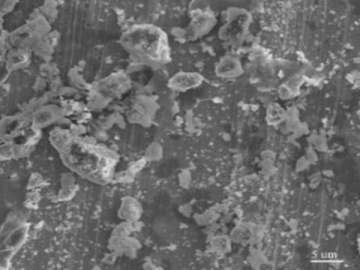

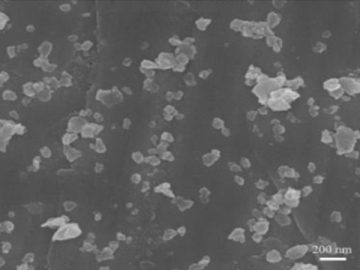

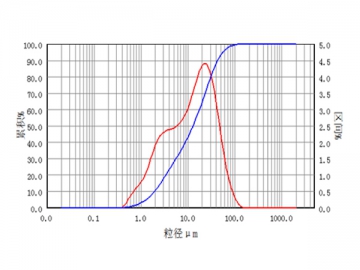

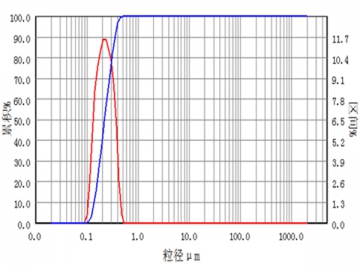

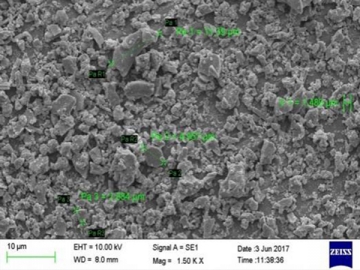

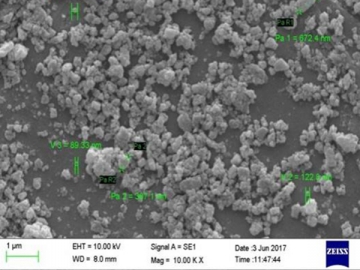

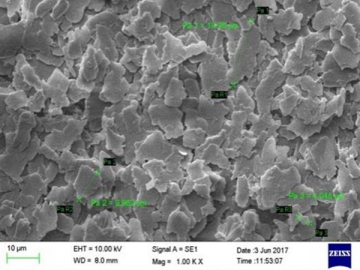

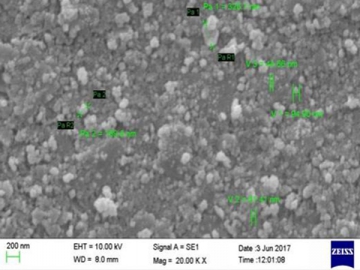

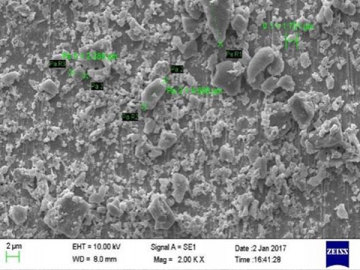

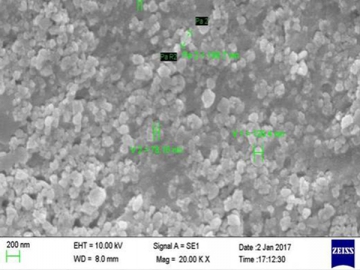

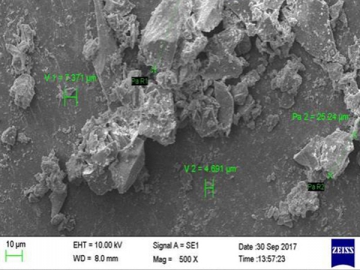

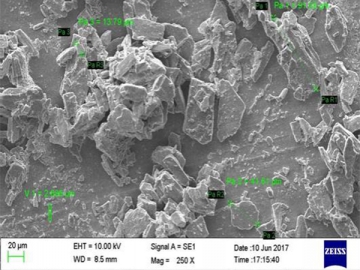

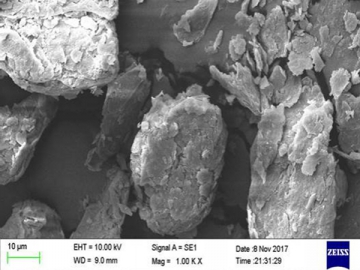

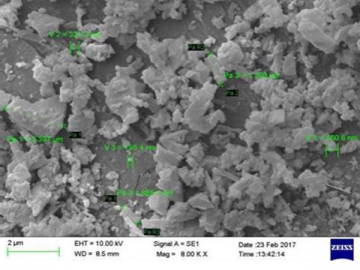

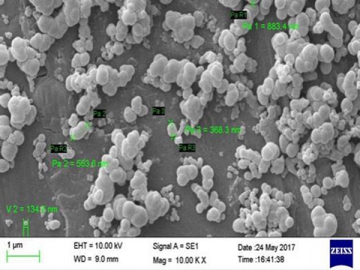

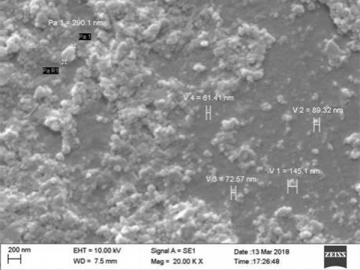

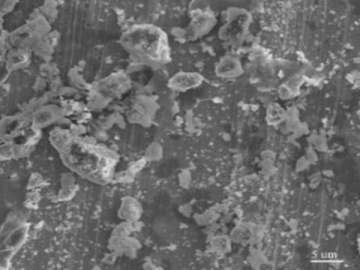

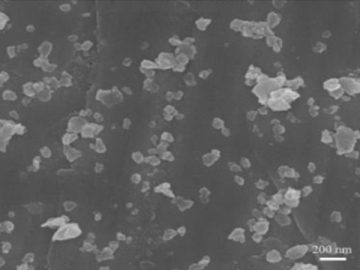

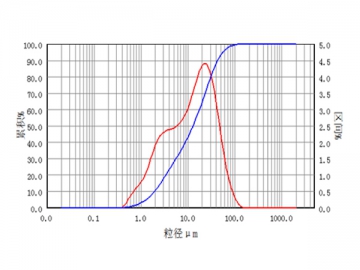

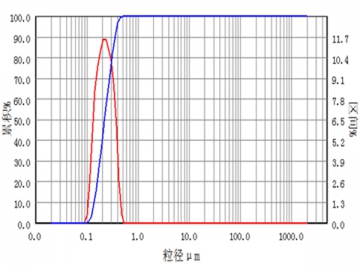

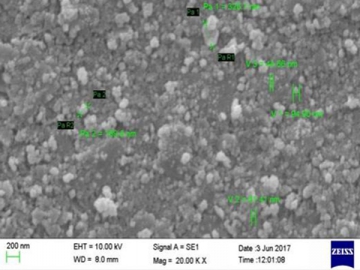

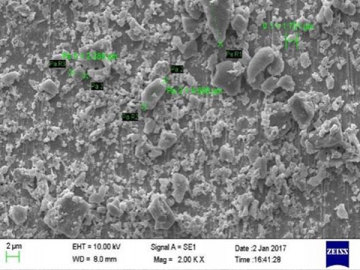

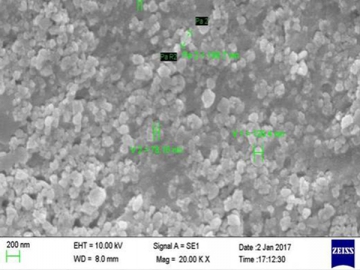

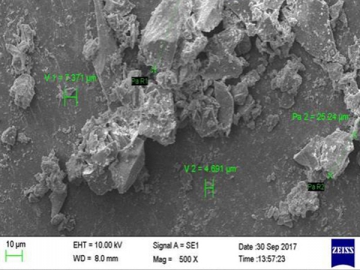

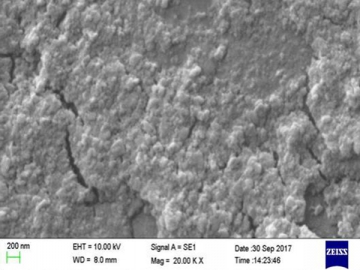

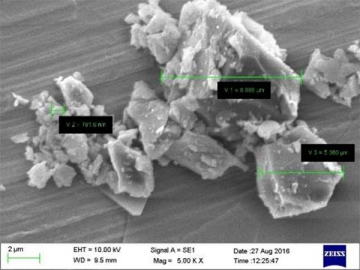

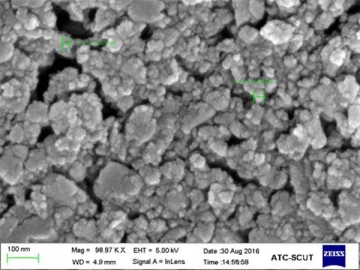

Shown here are the ultrafine grinding results for different mineral using our attrition mills. It is clearly displayed that ultrafine grinding carried out by our grinding mills results in a significantly smaller particle size and more uniform mineral powder distribution.

With our experienced team, we also offer customized grinding solutions upon request. Please feel free to contact us.

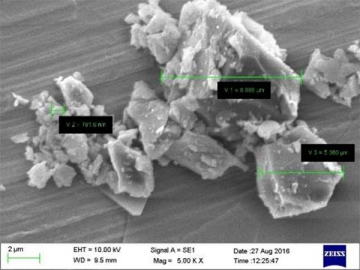

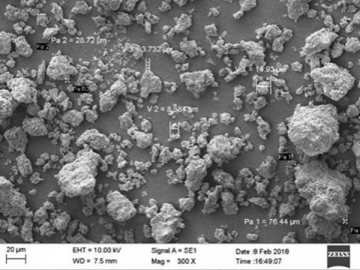

Zeolite grinding - Before grinding

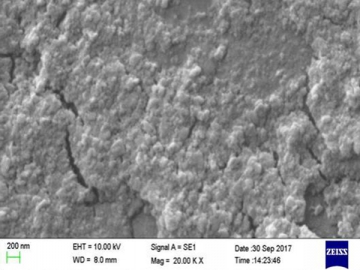

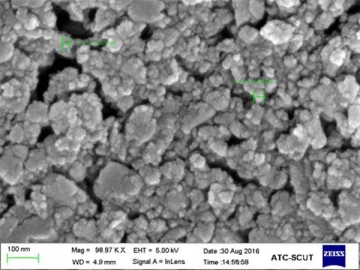

- After grinding

| Grinding time | 0h | 2h | 7h | 10h |

| D50(μm) | 18.00 | 0.25 | 0.15 | 0.07 |

| D90(μm) | 30.00 | 0.40 | 0.25 | 0.10 |

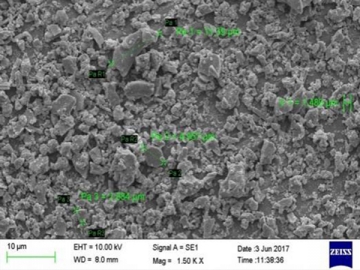

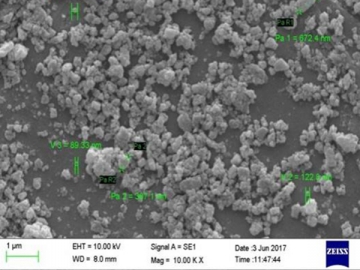

- Before grinding

- After grinding

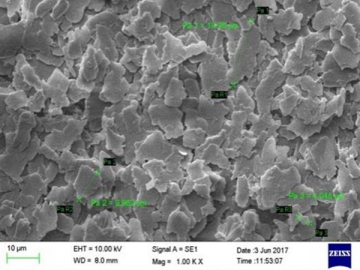

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 3.87 | 0.06 |

| D90(μm) | 11.54 | 0.07 |

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 6.30 | 0.38 |

| D90(μm) | 12.60 | 0.45 |

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 7.20 | 0.10 |

| D90(μm) | 16.20 | 0.33 |

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 2.1 | 0.1 |

| D90(μm) | 10 | 0.2 |

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 32.00 | 0.10 |

| D90(μm) | 50.00 | 0.16 |

- Before grinding

- After grinding

| Characterized size | Feed | Product |

| D50(μm) | 3.87 | 0.06 |

| D90(μm) | 11.54 | 0.07 |