Mobile Phone PCB Soldering

OKATA GT-HJ series soldering machine features 5 axes and rotary soldering function. Double soldering gun and PC touch screen can be added to perform drag welding and spot welding. Furthermore, this automatic soldering machine has simple operations and high efficiency, greatly reducing labor cost.

The mobile phone is a high-precision product and the phone will not work at all with a component assembly failure. OKATA strictly monitors and controls every step of our production processes. For soldering process, the component is usually very small and requires high precision. But the manual work often makes short circuit and the low soldering efficiency and poor soldering quality stability are also serious problems. As a result, an automatic soldering machine is much more suitable for handling mobile phone PCB.

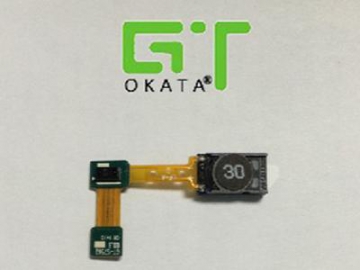

Customer’s FPC is mainly used in mobile phone screen, which requires the solder joint full and smooth. Each circuit board should be cleaned once. 0.5mm solder wire required. Double efficiency as manual work.

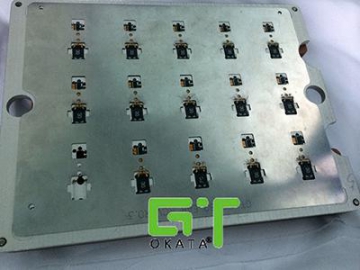

Jig

According to client’s production efficiency requirements and product specifications, magnetic plate and clamping fixture are provided. Each fixture can accommodate 15 products, which can be soldered within 57 seconds.