PCB Soldering

PCB soldering Requirements

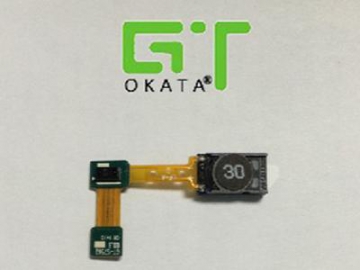

- The product of PCB is shown as follows and it needs to be welded with solder wire and 2cm of solder wire should be left aside. A proper solder joint is firm, smooth and full. Make sure to solder properly and don’t miss any point.

- The product is a component of a precise electric appliance, which requires the defective rate lower than 1‰.

Disadvantages of manual soldering

- The length of the left solder wire not easy to control;

- Unsmooth solder section and ununiform soldering joint;

- High defective rate, easy to be damaged and often be nonconductive;

- Low efficiency, long training time, high cost and management difficulties of laborers.

OKATA GT-HJ352DX fully automatic PCB soldering machine

Features

- Vertical fully automatic soldering system;

- PLC control, high stability, high position repetition precision;

- Simultaneous work of four soldering head greatly enhances soldering efficiency.

- Clamping fixture

- Self-designed rotary lock on clamping fixture allows to solder 8 products at a time, which relieving the operators from fixing the materials and they only need to load and unload materials.

Operations

The clamping fixture is designed to work on both sides. Loading the material, pressing the start button and then the soldering system will automatically handle the products as preset steps. Meanwhile, operators can load materials on the other side to improve efficiency.

Related products

Send Message

Most Recent

More

Other Products

Videos