Anti-corrosive Heat Exchanger for Pharmaceutical Industry

The pharmaceutical industry requires that heat exchangers used feature a high cleanliness and strong corrosion resistance characteristics. Because of that, we have designed our silicon carbide heat exchangers to have an excellent cleanliness, high corrosion resistance, oxidation resistance and erosion resistance. Our silicon carbide heat exchanger for corrosive media can withstand high concentrations of sulfuric acid, nitric acid, phosphoric acid, mixed acid, strong alkali, oxidants, and other corrosive materials. Silicon carbide is also the only ceramic material that does not corrode under exposure to hydrofluoric acid.

- Compared to a graphite heat exchanger, silicon carbide heat exchangers have a cleanliness rate that is acceptable for pharmaceutical food grade standards.

- The special double tube sheet heat exchanger structure prevents cross contamination between the treated mediums like sulfuric acid, nitric acid, and service media like water, alcohol.

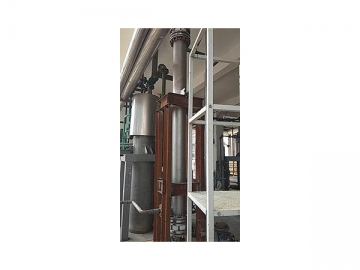

In 2017, a large domestic pharmaceutical manufacturing enterprise came to us with requirements for a highly anti-corrosive and high cleanliness grade heat exchanger to solve their material selection problems in other heat exchangers. After a site inspection and technical exchanges, our technicians put forward our solutions. We provided two double tube sheet silicon carbide heat exchangers, with the design temperature of 175 ℃, the design pressure of 0.6MPa, and the heat exchange area of 32m2 and 21m2 respectively to help customer solve their technical problems, and earned significant praise from them.

The unique double tube sheets silicon carbide heat exchanger meets the following high customer requirements:

- High corrosion resistance

- High grade of cleanliness

- Prevents cross contamination between the working medium and the service medium