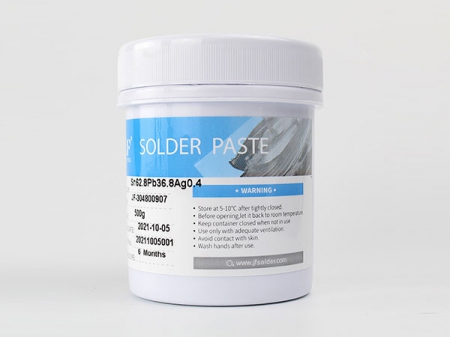

Sn62.8Pb36.8Ag0.4 Middle temperature solder paste

The Sn62.8Pb36.8Ag0.4 is a mid temperature tin lead solder paste. Its alloy is made up of 62.8% tin, 36.8% lead, and 0.4% silver content.

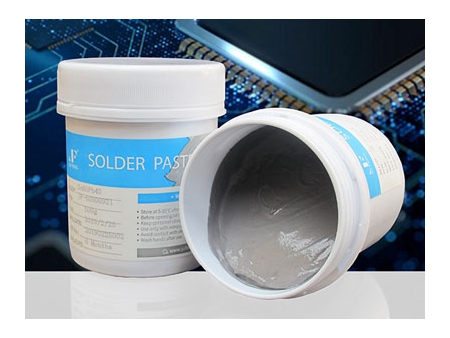

This kind of solder paste is a no-clean type solder cream designed for SMT production processes. It is made from special flux and tin spherical powder with few oxide contents. The paste maintains its viscosity allowing for a high level continuous printing effect. In addition, the flux contained in our Sn62.8Pb36.8Ag0.4 solder paste takes advantages of the high reliable low-ion type halogen activator. After reflow soldering, it has less residue, high surface insulation resistance, stable and reliable electrical performance.

Features- With nice fluidity and good soldering effect, the solder paste can accomplish the precision printing of circuit components, the separation distance of which can be only 0.2mm.

- There are very few changes of viscosity during the continuous printing process. The viscosity will not be altered, even after 12 hours of operation of the steel mesh.

- The original shape will not be changed after several hours of printing. In addition, the surface mount assembly will not be affected.

- Favorable wetting property on the substrate made from different materials.

- It can adapt to the requirements of multiple grades of welding equipment. It operates well without a nitrogen-filled environment or in a wide furnace temperature range for reflow soldering.

- Excellent welding performance during “heating then preservation” and “gradually heating” furnace settings.

- There is a special designed solder paste for BGA chip carrier, which can solve the problem of BGA welding.

- Good ICT test performance.

- It can be used for paste in hole processes.

1. Main standards and methods for quality control

ANSI/J-STD-004/005/006;

JIS Z 3197-86;

JIS Z 3283-86;

IPC-TM-650.

Alloy composition

| Composition | Content % |

| Sn % | 62.8±0.5 |

| Ag % | 0.4±0.1 |

| Pb % | Remainder |

| Cu % | ≤0.005 |

| Bi % | ≤0.03 |

| Fe % | ≤0.02 |

| As % | ≤0.01 |

| Ag % | ≤0.05 |

| Zn % | ≤0.002 |

| Al % | ≤0.001 |

| Pb % | ≤0.05 |

| Cd % | ≤0.002 |

| Sb % | ≤0.002 |

Related Names

Silver Brazing Paste | Tin Lead Soldering Paste | Soft Metal Solder Paste