SD-P09 Automatic Pulp Molding Machine

Description

SD-P09 automatic pulp molding machine production line adopts the German Siemens PLC control system to controls each movement of the process. The system can be used to monitor or adjust the action data required by the machine and it also can start and stop at will to continuously complete each process. The machine has stable production performance, advanced technology, easy operation and high automation. It achieved the tight combination of the mechanical properties and the production process and achieved the complete automation of the production process of paper pulp and environmental food products. The new technologies seize the international market, and will have a great advantage and business opportunities.

Application

SD-P09 automatic pulp molding machine can be used in the food packaging products which used plant fiber as raw materials (sugarcane ,bamboo, wheat straw, reed, wood). Those products including the plate, bowl, lunch boxes, supermarket tray and a variety of drinks cup, coffee cup, etc. It can be used in microwave oven, oven baked food, frozen and distillation food, besides it can also used for industrial packaging and commodities.

- Plate

- Bowl

- Box

- Tray

- Cup

- Slipper

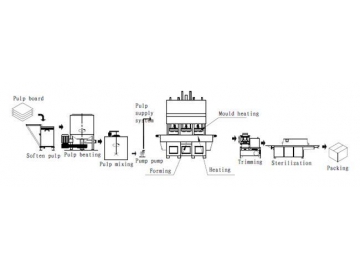

Production process analysis

1. The pulping process is to make the quantitatively soaked pulp plate into paper pulp. The first step is finished by hydraulic pulping machine and let the pulp into the tank, adding edible grade waterproofing and anti-oil additives, and then into the pool. Secondly, the pulp is send to the automatic molding machine for precise quantitative grouting, and then use the hydraulic stir mix the pulp, then vacuum dehydration.

2. Modeling is one of the most important step in this production line, it's working principle is to quantitatively provide pulp, backwash hydraulic homogenate , vacuum absorb dehydration. Advanced technologies are used in the modeling process to eliminate perforation, uneven thickness and reduced waste. Finally, after modeling, those tableware are manually transferred to the thermostatic solidified mold for dehydration and solidification.

3. The modeling process adopts the patent technology ZL 2008 20101990.8. Compared to the traditional heating device, it can reduced 70% electric consumption and 30% production cost. The process meet the hygienic requirement of food packaging , it not only improve the energy utilization efficiency, but also ensure high yield and high quality, with a yield rate of more than 98%.

4. The molded semi-finished product not need to cut edge. After demold from the mold manipulator , then collect and finished product production can meet the factory requirement. Products can be disinfected and packaged into the warehouse.

Technical Specification| Item | Technical data | Notes |

| Dimension | 5700*2600*4100mm mm | Manufacture provide |

| Weight | 18T | Manufacture provide |

| Size | 1200*1050mm | Manufacture provide |

| Capacity | 7.5KW | |

| Circulation time | 60s | calculate use standard disk (16g) |

| Range | ±1.5g-25g | Product standard weight±1.5-25 g |

| Maxium power | 190KW | Manufacture provide |

| Height | ≦100 mm | |

| Daily capacity | 700KG(46000) | calculate use standard 9inch disk (16g) |

| Yield | ≧95% | Meet the company's product appearance inspection standard |

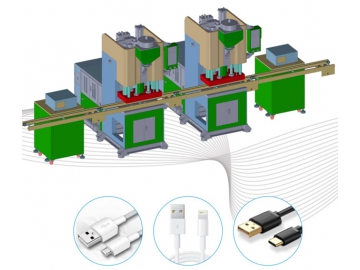

Production line

1. All parts of the machine which contact the pulps including pipes and valves all made of stainless steel, and therefore have good resistance to corrosion and heat.

2. The mold of the forming machine and molding machine both use the alloy copper or (7075 alloy aluminum) material with high thermal conductivity, high abrasion resistance and high strength and high conductivity.

3. Far east company's innovative energy-saving hydraulic device design has been patented.

4. Two different heating method : a. heat, b.oil.

5. The hydraulic pressure is adopt in the heat pressure mode and the pressure can reach 15Mpa. The high pressure make the product more dense and the good physical strength.

6. The safety operation rate of the equipment is 95% and safely operate for 24 hour.

Low cost of the SD-P09 automatic pulp molding machine

1. High degree of automation, can be supervised by one person, which greatly reduces the cost.

2. Using the patented advanced technology , which can reduce 70% of consumption compared with traditional electric heated device. Negative pressure was adopted in the production process from the molded material to mold (alternative manipulator), which largely reduce the labor intensity compared with the semi-automatic manual transfer.

3. The utility of the fixed form of wire mesh mode was increased by 20 times, which reduces the loss of network (eliminates attach to the steel wire) to reduce the production cost by a fifth.

4. Automatic operation from quantitative for pulp, suction forming, cold pressure dehydration, pressure change transfer, thermal solidification, product ejection and collection, which reduce 80% of operators compared to the semi-automatic equipment and reduce labor intense as well as industrial injury risk.

5. Pioneering innovation of the energy-saving "free cutting edge" technology, and the most new production equipment for the food tableware , which can cut the cost of production to 10%.

6. Automatic stop and alarm during failure, which can reduce losses.