Forming Fabrics for Paper Machine

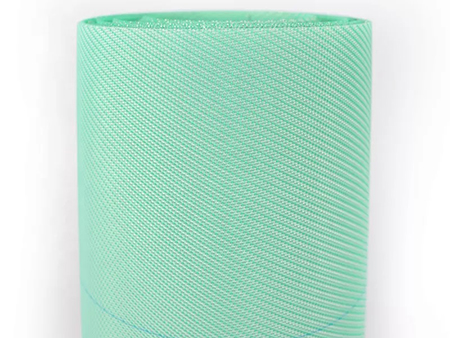

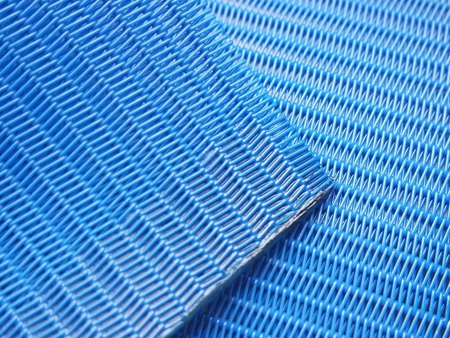

As an indispensable part of the paper machine, the forming fabric is a component for paper forming and dewatering on the equipment, which is generally used for dewatering of pulp suspensions as well as streamlining of work procedures. And the forming fabric is usually made up of woven polyester monofilament. Furthermore, the high abrasion resistance of the forming fabric is guaranteed by adding nylon monofilaments in the weft to prolong the service life of the paper machine forming fabrics. Additionally, our forming fabrics are linked by connecting the warp yarn at the end of each fabric, so as to make endless loops. More importantly, fully automated seaming machines for connecting fabrics are put into use to optimize the quality of those endless loops.

- Excellent abrasion-resistant potential with low fabric consumption;

- Even paper profiles with outstanding quality;

- With amazing versatility (all paper grades and all types of paper, board, and tissue can be manufactured);

- High working efficiency, alkali-resistant, acid-resistant;

- Combined with lightweight and compactness;

- Easy to transport, simple to operate and easy to maintain;

- Long fabric life;

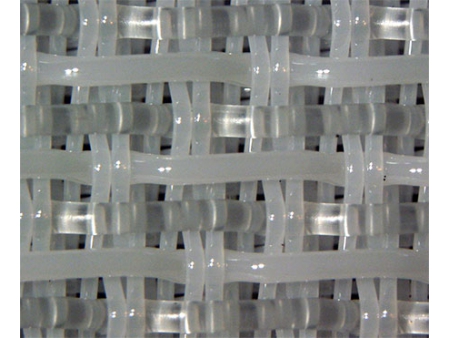

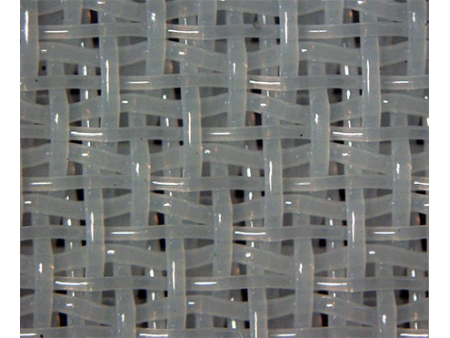

The paper machine forming fabrics can be classified into five different series, including single-layer forming fabric, double-layer forming fabric, 1.5-layer forming fabric, 2.5-layer forming fabric and SSB 3-layer forming fabric, which are as follows:

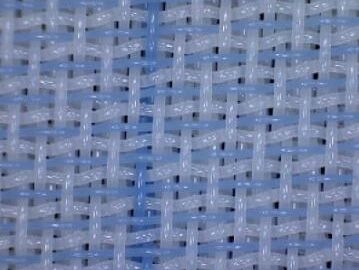

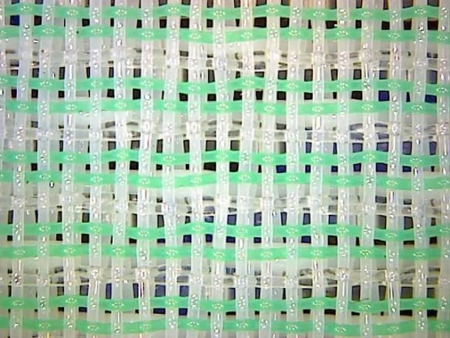

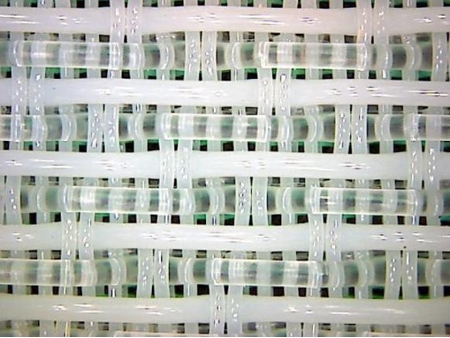

As we know, the single-layer forming fabric is commonly used to manufacture quality kraft paper, tissue, writing and printing paper and it is typically produced into 4-shed, 5-shed and 8-shed series single layer polyester forming fabrics, among which, the 4-shed and 5-shed series single-layer polyester forming fabrics are the two widely used polyester forming fabric in paper making, mainly used for producing cultural paper, printing paper, as well as packing paper. 8-shed single-layer polyester forming fabric is well suitable for kraft paper, kraft paper bags, cardboard, corrugated paper making, etc. Also, it can be used for producing common printing paper. And this polyester forming fabric is one of the most wear-resistant single-layer forming fabric with long service life and relatively deep wire mark.

As an original design of the Huatao forming fabric, the 1.5-layer forming fabric is a 5-shed single-layer fabric woven with an additional layer of yarn, giving it properties usually found in double-layer fabrics. And this additional layer of yarn provides better sheet side smoothness as well as improved retention. Owing to its unique structure, this 1.5-layer forming fabric delivers stunningly great drainage and ease of cleaning. With a wide range of applications, this paper machine clothing is mainly used for producing cultural paper, printing paper, glazed paper, packing paper and common newsprint. Compared with single-layer forming fabric, this 1.5-layer forming fabric has longer service life and good air permeability, generally used in packing paper machines with machine speed of 50m-400m/min.

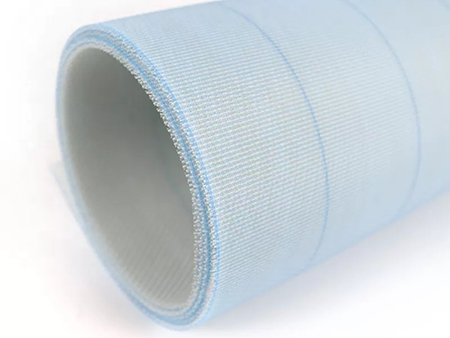

HUATAO double-layer forming fabric is generally featured with a double-layer weft structure. Compared with single-layer forming fabric, densities of warp and weft are even higher. And this double-layer forming fabric is more dimensionally stable but less stretchable. Thanks to the large three-dimensional space, our double-layer forming fabric also provides excellent drainage property. Drainage force does not directly affect the paper layer, which helps improve retention. When it comes to its wide applications, the double-layer forming fabric is widely used in medium and high speed paper making machines, producing printing paper, household paper, packing paper, cardboard, newsprint, etc.

The 2.5-layer forming fabric is of course one of our best-selling products and is widely used in paper machines with a speed range of 200-500 m/min. And the 2.5-layer forming fabric is mainly used to manufacture printing paper, packing paper, cardboard, onion-skin paper, newsprint, household paper, etc.

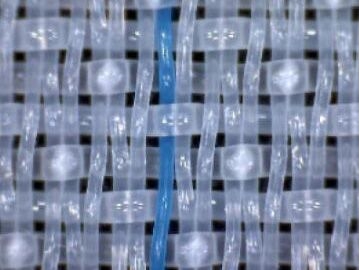

As you can see, Huatao supplies quality SSB (sheet support binder) 3-layer forming fabric with compact design. So as to drain quickly and improve retention, this triple-layer forming fabric is typically manufactured to increase yarns density, which accordingly ensures better sheet support, great retention, as well as wire marks reduction. With little internal abrasion, the SSB (sheet support binder) fabric is used to produce highly qualified printing paper, tissue and cigarette paper, etc. Due to its excellent drainage and abrasion resistance, the up-to-date forming fabric is absolutely your optimal and ideal choice for high-speed paper machines.

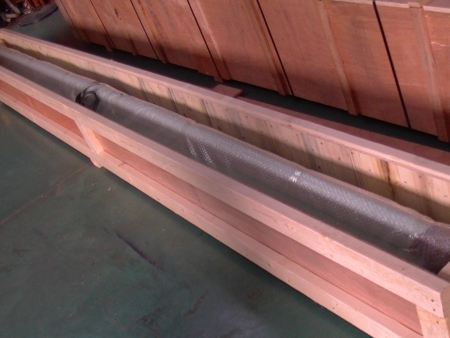

Packaging