Dryer Fabrics for Paper Machine

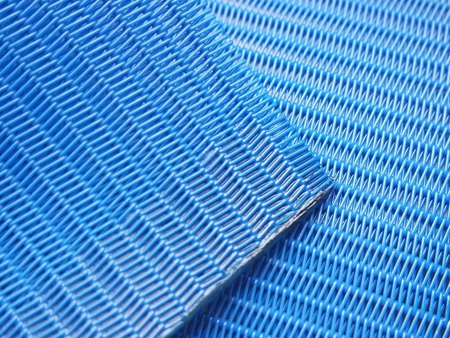

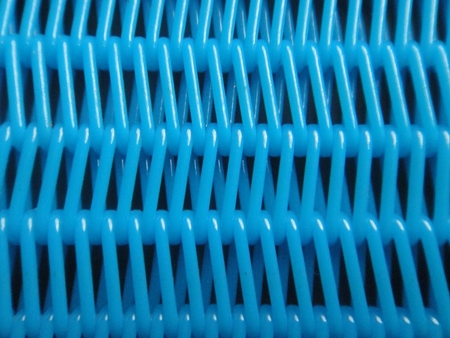

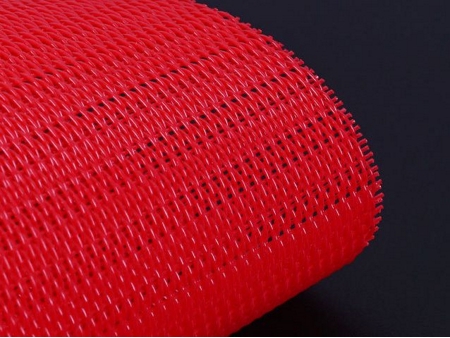

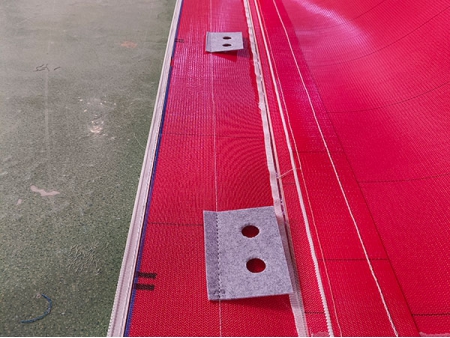

Huatao offers excellent dryer fabric product portfolios, including spiral dryer fabric and woven dryer fabric. When talking of the polyester spiral dryer fabric, the seamless spiral dryer fabric has the capability to withstand mechanical strain. And this spiral dryer fabric is specially designed for drying positions where damage to the seam occurs. And it is exactly made of hydrolysis and abrasion resistant PET, thus ensuring high standard wear resistance. Furthermore, it is widely used for the production of cultural paper (writing paper, printing paper), packing paper (kraft paper, Chinese noodles packaging paper, corrugated fluting paper, etc.), paper for exclusive use (train tickets), etc. In addition, this dryer fabric can also be applicable for filtration and screening in environmental protection, pharmaceutical, mining, metallurgical and mechanical industries.

Features- Spiral dryer fabric can be customized that are tailored to your various permeability requirements;

- No problems with the seam;

- No wire marking;

- High dimensional and diagonal stability;

- Even tension profile;

- Excellent wear resistance and outstanding durability;

- With good air permeability, thus improving drying effects and drying efficiency;

- Wide air permeability range;

- Easy for installation and maintenance;

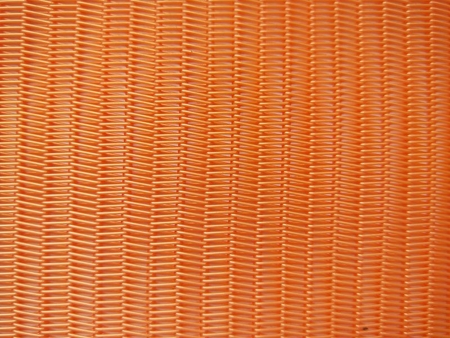

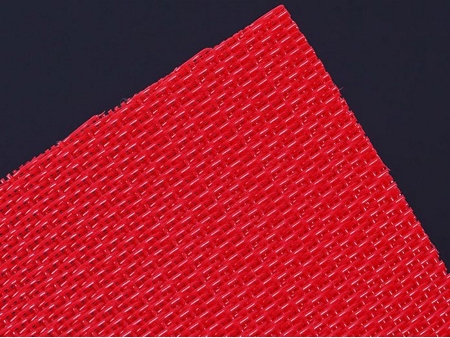

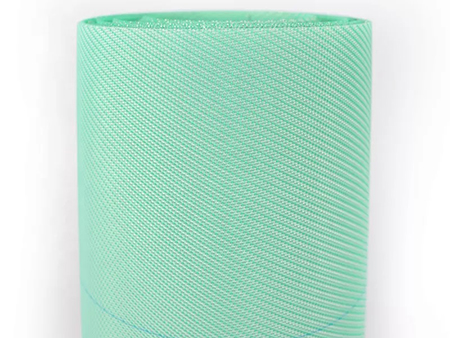

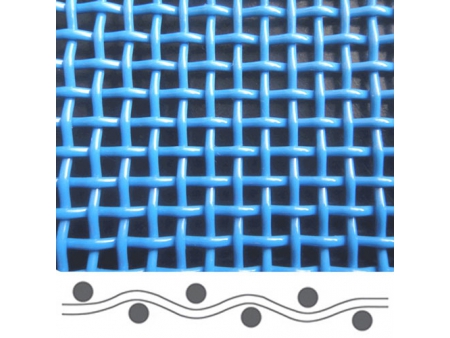

Designed with mature concept, Huatao woven dryer fabric is basically categorized into 3-shed, 4-shed and 8-shed. Woven with round and flat monofilaments, the woven dryer screen can absolutely meet your various needs, including drying of different paper grades and drying speed. More specifically, different yarn structures and shapes are used to control air permeability, as well as providing large contact area, thus ensuring better heat transfer and appropriate permeability. Moreover, the woven dryer fabric is widely applied for the production of tissue paper, newsprint, writing paper, printing paper, etc.

Features- Hydrolysis resistance in wet conditions and degradation resistance in dry and hot conditions (red polyester monofilaments);

- Smooth surface (flat monofilaments);

- PPS (phenylene sulfide) material is utilized for protection from damaging under harsh conditions;

- For papers that require excellent printability;

- Large contact area and excellent heat dissipation;

- Low stretch and high structural stability;

- Highly efficient drying;

- Strong and non-marking seam;