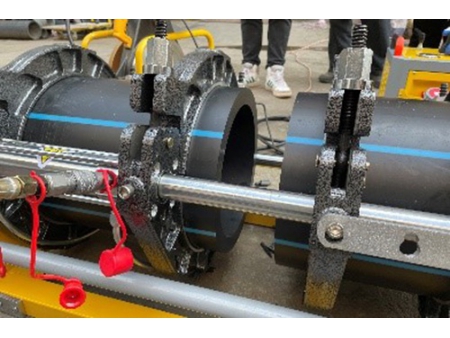

Hydraulic Butt Fusion Machine, WP160A

Request a Quote

63mm-160mm Plastic Pipe Welding Machine

The butt welding machine is ideal for butt fusion joining of HDPE, PP, PVDF, MPP pipes and fittings.

- Model: WP160A

- Welding range: 63-160 mm

- Applicable pipe diameters: 63-75-90-110-125-140-160 mm

- Optional reducers: 40-50mm

- Power supply: 220 V/50Hz, 1PH

- Total power: 3.35 kW

- Heating plate: 1.5 kW

- Planing tool: 1.1 kW

- Hydraulic station: 0.75 kW

- Pressure adjusting range: 0-8 MPa

- Max temperature of heating plate: 270 ºC

- Temperature deviation: ±5 ºC

Application

WP160A hydraulic butt fusion machine is ideal for welding HDPE, PP, PVDF, MPP pipes.

Features

-

The machine frame is sturdy and distortion-free, ideally suitable for heavy-duty applications.

-

Steel plates of the machine frame are precisely cut to achieve high precision and aesthetic appearance.

-

Enclosed hydraulic station is designed to prevent dirt or water. LCD display panel and data logging device are optional upon request.

-

Copper coil motor has a self-locking system to prevent damages caused by misoperation. High-speed steel reducer inserts with double cutting edges are highly durable.

-

High quality resistance wire delivers excellent heating performance. The heating element is applied with superior Dupont or Daikin coating.

Packaging & Shipping