Linear Motor Two-way Oil Well Pump

Oil pump/ Two-way pump/ Oil extraction pump

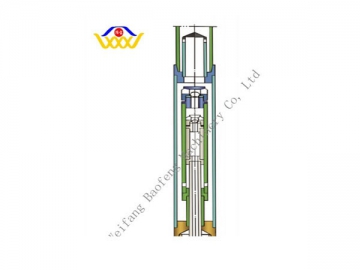

The linear motor two-way oil well pump is designed for liner motor driven oil recovery in a variety of oil extraction operations.

Applications :

1. This pump is employed in oil wells where conventional beam pumping units can be used. (Small displacement deep pumping wells, intermittent production wells, displacement ≤15t / d, pump hanging ≤3000m) The process technology doesn’t change.

2. This pump can also be used in oil wells where the conventional beam pumping units cannot be used. (Offshore wells, horizontal wells, directional wells, inclined wells, slant wells, low permeability wells, etc.)

3. It can also be applied in low liquid content high oil-gas ratio oil wells, low liquid content high condensate oil wells and low liquid heavy oil wells with stock tank oil viscosity ≤3000mPa.s at 50℃. The sand content of produced liquid < 0.05%.

Working Performance

Older model linear motor oil pumps only lifts oil in the upstroke, which places a large load on the motor and wastes energy during down strokes. This new pump achieves pumping oil in both up and down strokes. For the same displacement and pressure, two-way oil well pumps can reduce the stress on the rotor of motors and energy consumption of motors.

Structure Features

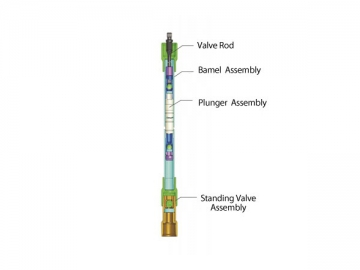

1. This pump has two barrels and two plungers specially assembled. It can pump oil in up and down two ways.

2. This pump has screen pipe, avoiding the sliver sand, rust, scale piece and other dirty setting in the pump.

3. This pump has special sealed sand scraping device, avoiding the sand getting into the motor.

4. The pump barrel uses new heat technology (invention patent), get stronger anti-corrosion and wear resistance.

5. Assembled with tungsten-carbide ball and ball seat, double service life than stainless steel ball seat.

Pump ready for delivery to Venezuela!

Technical Parameters:

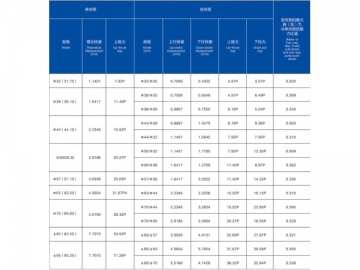

| One-way pump | Two-way pump | Ration of two-way Max. Push(Pull) stress and one-way pump push stress | ||||||

| Model | Theoretical displacement(m3/d) | Up-thrust(kg) | Model(mm) | UP stroke displacement(m3/d) | Down stroke displacement(m3/d) | Up-thrust(kg) | Down pull(kg) | |

| φ32(31.75) | 1.1401 | 7.9P | φ32/φ25 | 0.7069 | 0.4332 | 4.91P | 3.01P | 0.620 |

| φ38(38.10) | 1.6417 | 11.40P | φ38/φ25 | 0.7069 | 0.9348 | 4.91P | 6.49 P | 0.569 |

| φ38/φ28 | 0.8867 | 0.7550 | 6.16P | 5.24 P | 0.540 | |||

| φ44(44.15) | 2.2346 | 15.52P | φ44/φ28 | 0.8867 | 1.3479 | 6.16P | 9.36 P | 0.603 |

| φ44/φ32 | 1.1401 | 1.0945 | 7.92P | 7.60P | 0.510 | |||

| φ50(50.8) | 2.9186 | 20.27P | φ50/φ32 | 1.1401 | 1.7785 | 7.92P | 12.35P | 0.609 |

| φ44/φ38 | 1.6417 | 1.2769 | 11.40P | 8.87P | 0.562 | |||

| φ57 (57.15) | 3.6939 | 25.65P | φ57/φ38 | 1.6417 | 2.0522 | 11.40P | 14.25P | 0.556 |

| φ63 (63.50) | 4.5604 | 31.67P4 | φ563/φ44 | 2.2346 | 2.3258 | 15.52P | 16.15P | 0.510 |

| φ70(69.85) | 5.5180 | 38.32P | φ70/φ44 | 2.2346 | 3.2834 | 15.52P | 22.80P | 0.595 |

| φ70/φ50 | 2.9186 | 2.5994 | 20.27P | 18.05P | 0.529 | |||

| φ83(82.55) | 7.7070 | 53.52P | φ83/φ57 | 3.6939 | 4.0131 | 25.69P | 27.87P | 0.521 |

| φ95(95.25) | 7.7070 | 71.26P | φ95/φ63 | 4.5604 | 5.7004 | 31.67P | 39.59P | 0.556 |

| φ95/φ70 | 5.5180 | 4.7428 | 38.32P | 32.94P | 0.538 | |||