UHMWPE Pipe Extrusion Machine

(Plastic Pipe Extrusion Machine, 63-1200mm)

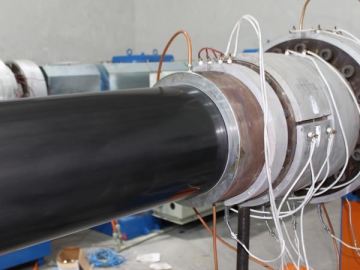

The UHMWPE pipe extrusion machine supports production of UHMWPE pipes with diameter from 63 to 1200mm. Adopting die cooling method, this plastic pipe extrusion line designed based on our patented technologies realizes continuous production of plastic pipes.

Comparing with similar plastic extrusion equipment, our UHMWPE pipe extrusion machine has 1/3 higher pipe production capacity, 1/4 less energy consumption, and much better pipe quality.

Features of the UHMWPE pipe extrusion machine

1. According to our years of experiment and practice, the small screw pitch and big screw diameter are adopted for our UHMWPE pipe extrusion line. The production line can melt the UHMWPE, whose melt index is near 0, and slowly extrude it continuously.

2. Our UHMWPE pipe extruder, comparing with normal plastic pipe extrusion machine, doesn’t need the cooling fan for the spiral barrel. Each section of the UHMWPE pipe extrusion machine comes with an independent control system, so the temperature precision and energy efficiency are both great. The main motor is optimized for the line, leading to 25% reduction in energy consumption.

3. To shaping the pipe with cooled mold, we add to the nozzle and core rod. Low temperature heat conduction oil will be injected into the pipe through the mold temperature control mechanism to cool the mold and shape the pipe material. In comparison to regular PE pipe extrusion machinery, our UHMWPE pipe extrusion machine is much cheaper due to the absence of vacuum shaping sleeve, vacuum box, and traction machine. Besides, high molecular material with a molecular weight as high as 1.5-5 million, like UHMWPE, can be processed.

To achieve the UHMWPE pipe shape forming and mold cooling, spiral outer flow channel and inner channel added to the nozzle of the mold and the end of the screw. Low temperature heat conductive oil is injected into the channels through the mold temperature controller to cool the mold. Then the pipe about to come out of mold will be cooled and the shape can be formed.

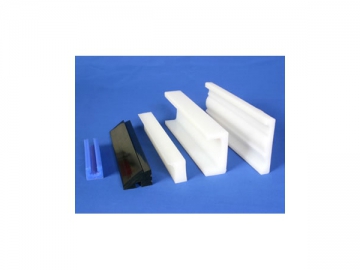

4. After changing the mold, the UHMWPE pipe extrusion machine can be used for producing sectional material and bar material.

The UHMWPE pipe is widely used for conveying various kinds of powder, slurry, and gas materials, such as ore, grain, sand, dirt, ash (from power plant), sea/river water, oil, natural gas, chemicals, and so on. It can replace the iron pipe, steel pipe, stainless steel pipe, and steel alloy pipe.

Main equipment of the UHMWPE pipe extrusion machine

1. Ultra-high molecular weight material extruder

2. Mold and mold temperature controller

3. Pipe bracket

- Ultra-high molecular material extruder

- Mold and mold temperature controller

| Extruder type | ||||

| Pipe diameter range (mm) | Ф63- Ф 159 | Ф 159- Ф 500 | Ф 500- Ф 800 | Ф 800- Ф 1200 |

| Main motor power (kW) | 22 | 37 | 55 | 75 |

| Extrusion capacity (kg/h) | 5-20 | 10-40 | 30-80 | 40-120 |

| Bracket length (mm) | Customizable | |||

| Total installed power (kW) | <45 | <65 | <85 | <120 |