Copper Extruder Line

Continuous Extrusion Machine for Copper Wire

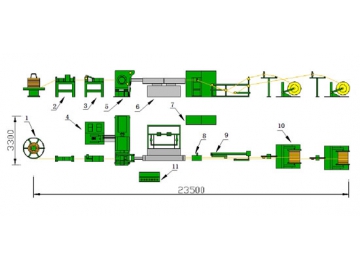

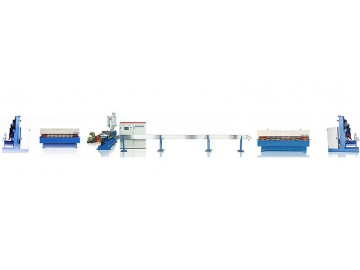

This series of extrusion lines are composed of eight parts: pay-off system, wire straightener, continuous extrusion machine, cooling system, length counter, take-up stands, high pressure hydraulic system and electrical control system.

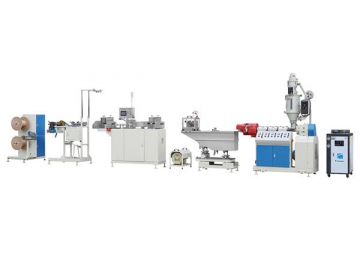

The blanks adopt up-casting oxygen free copper rods. Copper rods with clean surfaces are released from pay-off rolls. After being straightened, they are sent to continuous extrusion machine to form wire or plate profiles. The products at this time have high temperature, so cooling and anti-oxidation device is designed at the products outlet of extruder. Passing through length counter, the products are directly rolled.

Due to the simplification of production procedure, this metal extruder helps to reduce raw material consumption and save production cost. Material extrusion adopts thermal deformation method eliminating the need of annealing process, which ensures low energy consumption and decreases procurement investment.

Related:Copper Wire Line, Copper Wire Manufacturing, Copper Wire Manufacturing Process, Continuous Rotary Extrusion Equipment Manufacturer