Ferrous Metal VCI Antirust Paper

Description

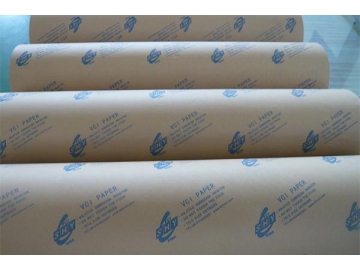

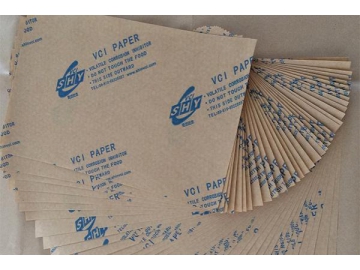

Ferrous metal VCI antirust paper utilizes a special Kraft paper as its base, then, with the use of a coating machine, a corrosion inhibitor in different formulations is coated to the surface of the paper in order to create a special rust prevention packaging material. This anti-rust paper can also be manufactured for secondary functions through an extra and deep processing. The VCI anti-rust paper is extremely vaporous, and can protect ferrous metals against corrosion for long periods of time, making it ideal for long-term storage or transportation by sea.

Application

Ferrous metal VCI antirust paper is an ideal corrosion protection packaging choice often used in the automobile manufacturing, mechanical and electrical product manufacturing, military manufacturing and more.

1. Automobile manufacturing industry: engine parts (crank shaft, cylinders, camshaft, flywheel), steel body stamping parts, pressure plate, cover and assembly of clutch, gas generator used for the airbag, transmission components, turbocharger

2. Mechanical and electrical products: motor rotor and stator, precision motor housing, powder metallurgical components, precision bearing, elevator parts, precision slide rail screw

3. Equipment manufacturing: wind power equipment, precision machine tool, rubber and plastic devices, printing machinery, high-end storage facilities

4. Electronics manufacturing industry: computer hard disk, computer case, power supply unit, battery shell, stamping parts

5. Other industries: shipbuilding industry, parts of high speed trains, military products

| Model | Structure | Standard Wide | Applications |

| 60g base paper +VCI | 787 or 1200mm | Applicable to corrosion protection of ferrous metals (steel, iron) and must not be used for non-ferrous metals | |

| PE+70g base paper +VCI | 1000mm | ||

| 40g base paper +VCI | 787mm |

| Anticorrosion method | Advantages | Disadvantage |

| Antirust oil/ butter | Inexpensive | 1. Extra treatment procedures and cleanliness required 2. Influences the quality of rubber, polyethylene and other similar products. 3. Causes severe pollution 4. Increases the cost of equipment 5. The rust prevention effect is easily influenced by temperature and external conditions. |

| Vacuum package /inert gas | 1. Excellent antirust effect 2. No need to clean 3. Can be used for non-metallic products | 1. Expensive packaging equipment is needed. 2. Easy to break during transportation. 3. Unable be used for large product sizes 4. Require higher packaging techniques. 5. Higher packaging cost |

| VCI anticorrosion | 1. Permeability of areas where a rust prevention oil can't cover. 2. Different physical states make it easy to package, transport and store. 3. Easy to use with no need for cleaning or immersion 4. Cost effective and environmental corrosion protective method | Must be sealed in an enclosed space |

Usage guide

1. It is necessary to ensure that packaged products are clean and rust free, with no exposure to other corrosive chemical materials on the product surface before packaging.

2. During the packaging process, the temperature of packaged products and the surrounding environment should remain constant through the entire operation.

3. When packaged products are large-scale equipment, large box inner packaging or intensive products, we recommend using VCI material such as rust prevention paper, rust prevention bags, rust prevention powder and other rust prevention materials.

4. No barrier should exist between the packaged products and the rust prevention paper, such as a paper pad, protective bag or plastic board. It should also be noted that other paper types and wooden material should not come into direct contact with the packaged products.

5. Users wear gloves through the entire operation process in order to prevent corrosion caused by sweat or other skin oils.

6. The packaging antirust paper should not remain exposed to open air for long periods of time before use. After packaging, the packaging container should be sealed as soon as possible using a heat seal, adhesive tape, or cable tie. Any remaining anti-rust paper should be resealed in an enclosed space.

Shinyue specializes in VCI packaging field, a reliable ferrous metal VCI antirust paper manufacturer and supplier. As VCI paper is volatile corrosion inhibitor paper, we offer VCI antirust paper sheet and paper rolls for industrial metal packaging, good in protection of the surface the ferrous metal and non-ferrous metal away from rust. Complete equipment with range from coating, winding and precision slitting, make us provide quality cost effective VCI antirust paper and film as well as custom metal antirust packaging solutions.