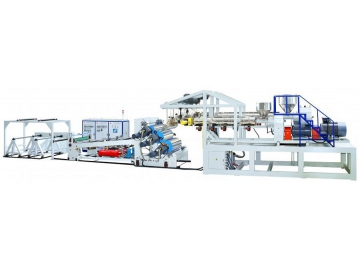

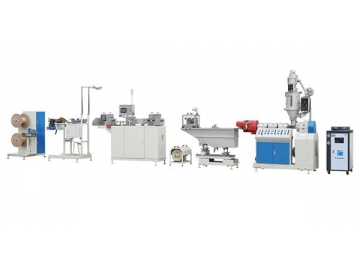

Precision angiography tube co-extrusion line

Angiography Tube Extrusion Line / Angiography Catheter Extrusion Line / Medical Tube Extrusion Line

An angiography catheter is also known as a developing tube. It is a thin plastic tube insert ed into arteries through a small incision in the patient’s skin, and is then guided to the area to be examined. Once there, a contrast dye is injected to allow images to be captured using a small dose of x-ray radiation. The catheter’s performance requires an excellent shape memory (resistance to deformation), a smooth wall, and a great imaging performance.

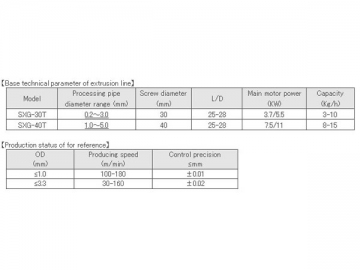

The imaging line of the angiography catheter’s inner duct wall is 3 or 4 roots in a uniform configuration, with its formation determined using a specially designed precision co-extrusion process. The special applications for the angiography catheter ensure the pipe size precision requirements are extremely accurate. The allowable tolerance should not be more than /- 0.02mm.

With more than 10 years of experience in research and development of medical tube extrusion, we are able to produce extrusion lines for catheters in specific sizes, section types, extrusion modes, and material performance.

Features of the Angiography Tube Extrusion Line

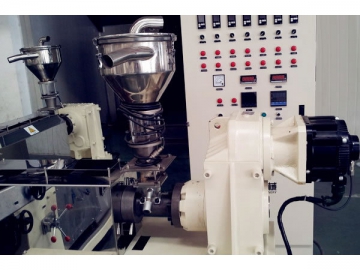

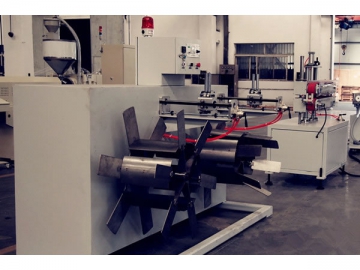

This extrusion machine driver uses a full servo system which gives the screw its rotating output with very little fluctuation. It also ensures the melt material extrusion fluctuation is controlled to within the lowest levels.

The extrusion line also uses a metering pump system, a stable material melt pressure and stable flow change, as well as an automatic feedback host speed for adjustments. This further reduces the melt material fluctuation before it goes into the extrusion mold.

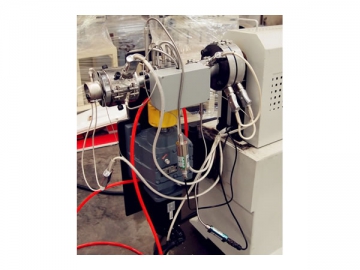

The catheter tube extrusion line uses an advanced CNC machine technology and electromechanical processing method to provide ideal extrusion for the tubes with a diameter of ≤1.0mm.

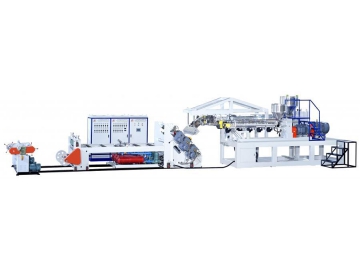

With the use of a new and accurate control of a weak vacuum technology, the vacuum and water system are controlled separately, with a vacuum accuracy of /-0.1Kpa.

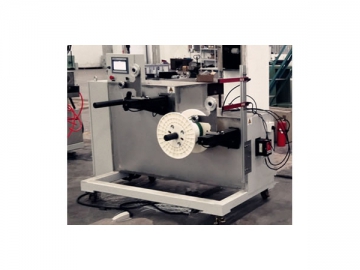

The high driving standard uses an independent up and down straight coupled servo motor driving system, which provides a pulling performance with close to zero fluctuation. The maximum line speed reaches up to 180m/minute.

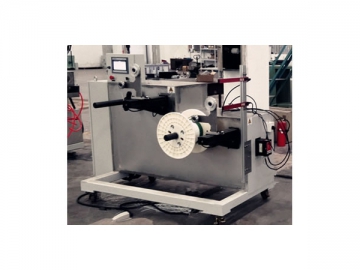

This medical tube extrusion line utilizes a double position automatic coiling on line, a winding device with an automatic adjusting line angle, and a special assembly tension adjusting device to avoid plastic pipe drawing from becoming strained.