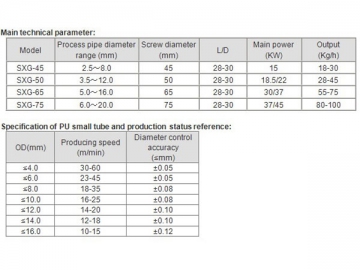

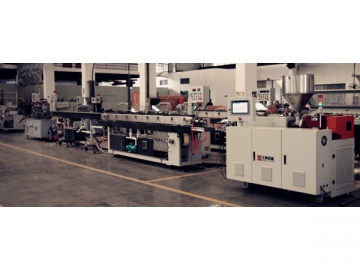

PU (polyurethane) precision tube extrusion line

PU Precision Tube Extrusion Line / Polyurethane Tube Extrusion Line / Precision Tube Extrusion Line

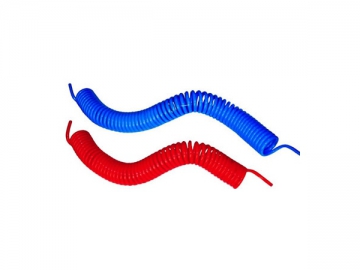

PU (polyurethane) tubes are known for their outstanding resistance to high pressure, vibration, corrosion, bending and weather. In addition, the PU pipes produced on the PU precision tube extrusion line are convenient and flexible, which is why this type of tube is widely used as an air pressure tube, pneumatic components, liquid conveyance pipe and protection tubes.

Equipment Features

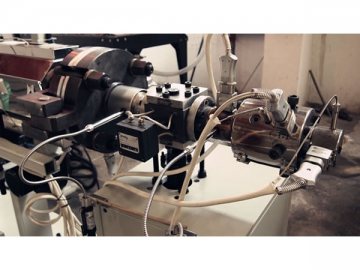

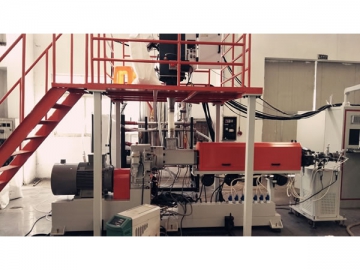

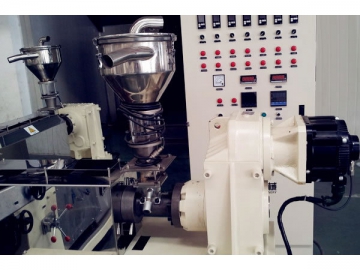

The PU screw utilizes an optimized Japanese technological processing, and can adapt to PU materials with a high thermal sensitivity, flow rate, and melting viscosity to ensure an even plasticization and high output efficiency.

The core rods and dies are made of Swedish ASSAB S136 die steel, and undergo a precision grinding to ensure the inner flow surface glossiness and corrosion resistance. The mold structure uses a high pressure volumetric type, which was developed using our own extrusion technology and provides a stable and high speed extrusion for tube material with very little fluctuation.

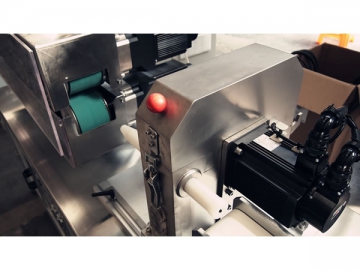

The high precision processed melting pump features a moving device for flexible moving. The front and back are equipped with a melt pressure sensor from the Italian brand GEFRAN, part of the front melt pressure closed loop feedback control system. This system offers a stable output and automatic extrusion fluctuation adjustment.

With a new automatic and accurate control of the vacuum technology, the vacuum and water system are separately controlled. By doing so, we can coordinate the multilevel water balance control system with the vacuum system and ensure a stable vacuum performance, cooling water level and water flow.

The high performance LaserMike measuring system forms a closed loop feedback control, which eliminates diameter deviation online.

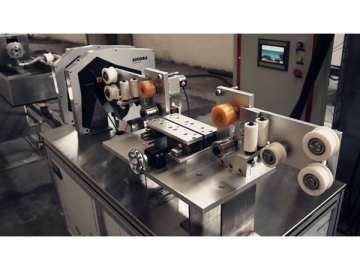

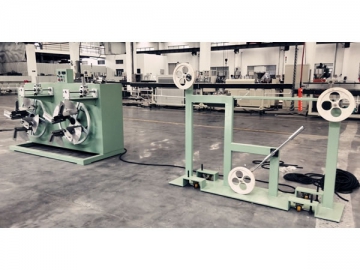

The puller is equipped with a multi-layer wear resistance synchronous belt, with no sliding. The high precision roller drive traction, YASKAWA servo driving system, or the ABB AC driving system all achieve a stable pulling performance.

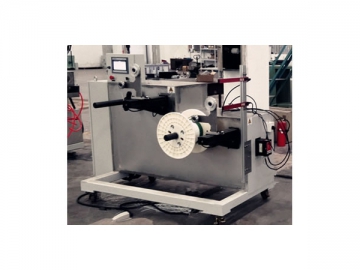

The specially designed winding machine has a tension induction regulator that applies to soft pipes and keeps the winding process under a natural relaxed state. When the tension conditions change, the fluctuation stays within a manageable scope to avoid tube overdrawing by a winding speed that is too fast or too slow.