Yarn Laminating Machine (Reciprocating Motion)

Different from the previous type of laminating equipment, this yarn laminating machine has no protective film laminating function. In the same time, the yarn laminator can finish the work used to require10 workers. What's more, the yarn laminating machine only needs one operator and achieves a process speed of 2400 pcs/hr. it’s an ideal choice for large-scale laminating projects thanks to its stable properties, small occupation area, simple structure, low cost, labor saving and high production.

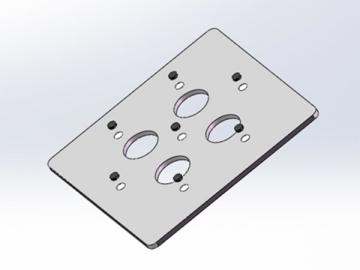

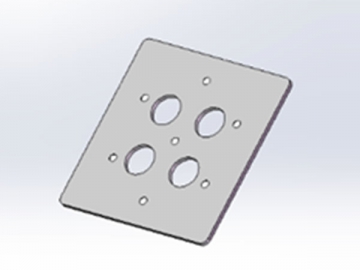

During the process, base plates are stacked together and can be fixed by internal holes, internal grooves or shapes. As for laminating materials, they are delivered in roll or sheet. The laminating process can be done in two ways, by a pressing head or a sucking head.

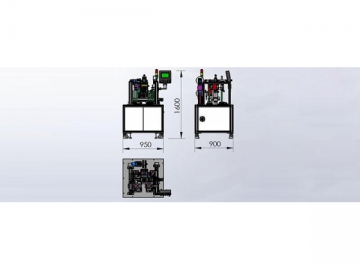

Specifications of Yarn Laminating Machine| Items | Parameters | Notes |

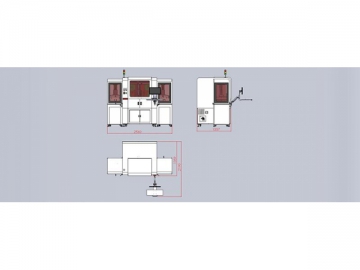

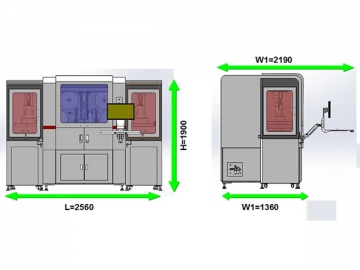

| Machine dimensions | L950mm×W900mm×H1600mm | |

| Workstation | 5 | |

| Size of base plate | Max: L150mm×W150mm | Can be designed upon request |

| Process zones | 2 feeding zones, 1 laminating zone, 2 discharging zone | |

| Feeding and discharging | Fully-automatic | |

| Anti-skipping | Every sucking head is installed with a vacuum detector that gives an alarm while a workpiece is skipped. | |

| Locating method | Locating pin | |

| Sucking head | 1 | |

| Laminating capacity | 1 pcs/time | |

| Laminating material | Yarn | |

| Laminating precision guarantee | Servo motor, lead screw | |

| Pneumatic elements | AirTAC | |

| Sensor | Omron, RIKO | |

| Locating precision | ±0.01 mm | |

| Leftover winding | Stepping motor | |

| Laminating precision | ±0.1 mm | |

| Repeating precision | ±0.05 mm | |

| Laminating methods | Pressing laminating, sucking laminating | |

| Laminating speed | 2400 pcs/hr | |

| Power | 2KW | |

| Workstation weight | 500 kg | |

| Power supply | AC 220V 50HZ |

Features and Benefits of Yarn Laminating Machine with Reciprocating Motion

1. The yarn laminating machinery is pretty flexible and its workstations can be exchanged, added and reduced.

2. Using the Mitsubishi control system, the yarn laminating machine runs stably and reliably.

3. All pneumatic components are from AirTAC to ensure long lasting performance of our machine.

4. With the combination of servo motor system and high-precision lead screw for feeding material, the laminator realizes high precision and fast speed.

5. High efficiency, high precision and material saving

6. When laminating different materials, user just needs to change the fixture, pressing head and sucking head. The machine has high adaptability and easy operation.

7. Laminating speed: 2400 pcs/hr.

8. A high degree of automation realizes a decrease in labor cost and product cost.

Samples