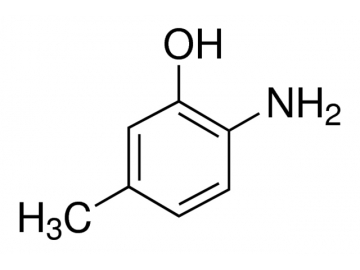

Amino Acrylsulphonate Phenol Formaldehyde Condensate Concrete Admixture

AS type amino

Our amino acrylsulphonatephenol formaldehyde condensate concrete admixture can be widely used to producehigh fluidity concrete, high strength concrete, no-vibration andself-compacting concrete, especially mass concrete and pumping concrete forlong-time and long-distance transport. With good steam curing adaptability, itcan be also applied for precastconcrete production in industrial and civil buildings and municipalengineering. In addition, our product can meet the needs of differentengineering for concrete performance and construction conditions if

Specifications

| Item | Specification |

| Appearance | Reddish brown powder |

| Solid content (%) | ≥ 92 |

| Fineness ( | ≤ 15 |

| Density, g/cm3 | 1.17±0.02 |

| Fluidity of cement paste (mm) | ≥ 230 |

| Alkali content (%) | ≤ 0.5 |

| Chloride, Cl - (%) | 0 |

| PH Value | 7~9 |

| Steel Bar Corrosion | None |

Dosage

Soliddosage ranges from 0.30% to 1.0% of the weight of

How to use and pack

1.Our product can be added directly or after being dissolved into water and itsstirring time should be properly prolonged to make full use of its dispersingcapacity. Besides, forced mixer is preferred for high strength concreteproduction.

2. Woven bag with plastic liner is adopted by our powder product with netweight of