Multifunctional Evaporator Formaldehyde Plant

The multi-functional evaporator process is the newest silver catalyst formaldehyde production process, and was independently researched and developed by the Helipont team. This patented process uses two specially designed absorption towers capable of producing 37-55% formaldehyde. We recommend this process for clients who require a high concentration of formaldehyde. Since 2010, we have supplied dozens of this plant type, with a stable quality, less space, and a 60TPD-400TPD capacity.

- Air roots blows

- Air washing tower

- Off-gas roots blower

- Steam Filter

- Multifunctional Evaporator

- Steam distributor

- Steam drum

- Reactor

- Desalted water

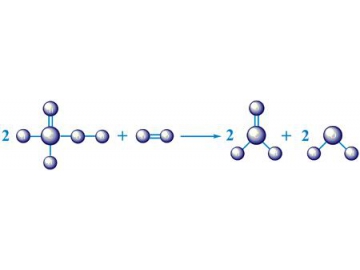

The air enters the multi-functional evaporator after filtration, washing and heating. After this process, the steam enters the evaporator. After heating, the circulation of off-gas from the top of the 2# absorber enters the evaporator. Finally, the filtered methanol liquid enters the methanol evaporator. These 4 gas types go through complex processes inside the methanol evaporator, including bubbling, heating, evaporation, mixing, separating and heating to obtain a quaternary gas. This process uses a hot formaldehyde solution to heat the methanol to the evaporation point, which saves water vapor. Quaternary gas enters the methanol reactor and goes through a redox reaction, thus forming formaldehyde gas. The formaldehyde gas from the reactor also includes steam, nitrogen, oxygen and hydrogen, and it needs the next absorption process to obtain a formaldehyde solution.

Product Specifications| Component | Index |

| Formaldehyde | 37-55% |

| Methanol | ≤1 wt. % |

| Formic Acid | ≤0.01 g/100 mL |

| Chloride | ≤0.0025 g/100 mL |

| Ashes | ≤0.01 g/100 mL |

| Particular | Index | Remark |

| Feedstock & Auxiliaries | ||

| Methanol(99.5%) | 0.445 ton for per ton of 37% formalin product | Expectation:442 ton |

| Catalyst (Silver) | As-per the Capacity | |

| Civil Utilities | ||

| Circulating Cooling Water | 40 ton for per ton of 37% formalin product | |

| Desalted Water | As-per the process | |

| Power Electricity (Voltage:415/250V; Frequency 50±0.5Hz) | 28 KWh for per ton of 37% formalin product | With 200kvA transformer |

| Steam for Startup(0.2Mpa) | 900kg/h | Need 3~4hrs |

| Export Steam as By-product(0.25MPa) | 150-200kg per ton of 37% formalin product | Without the Off-gas Boiler |

| Instrumental Air (P=0.5-0.7MPa(G)) | As-per the Capacity |

Projects Were Work on