Formaldehyde Plant

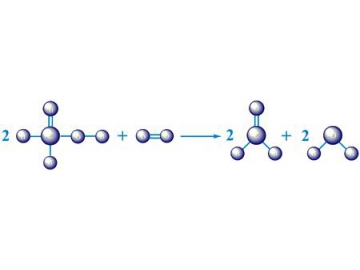

Formaldehyde is generated through the dehydrogenation or oxidation of methanol under a metal (such as silver or copper) catalysis process and is obtained by the decomposition of a hydrocarbon oxidation product. It is often used as a pesticide and disinfectant, and is the basic raw chemical material for the production of phenolic resin, urea-formaldehyde resin, vinylon, urotropine, pentaerythritol and dyes. Formaldehyde is widely used in the production of resins, plastics, leather, paper and fiber, and is an important part of everyday life.

Helipont has developed new production processes based on traditional formaldehyde production processes, backed by the aid of a number of senior engineers that are consistently seeking to improve production efficiency.

Formaldehyde Production Process

Metal oxide processes are used to produce a high formaldehyde concentration. The catalyst can be used for one year after each regeneration, which lowers costs and makes it a more economical solution.

Metal Oxide Process Formaldehyde Plant Project GalleryThe formaldehyde solution concentration produced through the silver catalyst process is 37-42%, reaching 55% with an evaporator. The silver catalyst used in this process requires a regeneration every 3 months, which often leads to higher costs. As a solution, Helipont has innovated and improved on the traditional process by replacing multiple evaporators with a multifunctional evaporator. Off gas absorption equipment designed by us ensures off gas meets direct emission standards, and the steam energy can be reused.

Silver Catalyst Process Formaldehyde Plant Project Gallery- 42% high concentration formaldehyde is available with the latest processes.

- Only 442kg-445kg methanol consumption for each ton of formaldehyde.

- Plant area occupation decreases by 6m×8m with the latest processes instead of a reboiler process.

- Larger silver catalyst filling amounts extend the service life by as much as 3 months when equipped with the latest off gas boiler. 500kg-600kg of steam will be generated for 1-ton of formaldehyde: i.e. 400kg-500kg from off-gas boiler steam drum and 100kg-150kg from reactor steam drum.

- The off gas through the absorption device will meet direct emission standards.