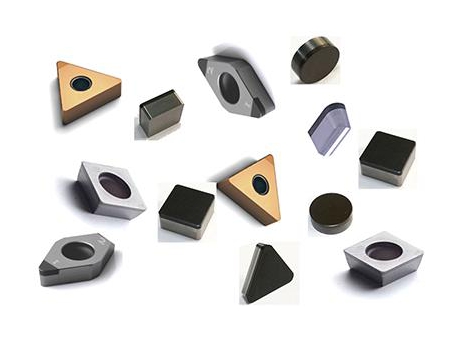

PCBN Wiper Insert

Description of PCBN Material:

Cubic boron nitride is the second hardest material in the world invented successfully in 1957. The hardness of CBN’s single crystal is HV8000-9000 while the hardness of PCBN is HV2500-5000, so its abrasive resistance is considerably better than tungsten carbide and ceramics. With high temperature oxidation resistance at 1000℃, CBN will do not have any chemical reaction together with ferrous material at 1200-1300℃. So CBN material is ideal for cutting ferrous materials, the CBN cutting tools are used for cutting hardened steel, cast iron, sintered iron as well as powder metallurgy components.

Features of PCBN Wiper Insert:

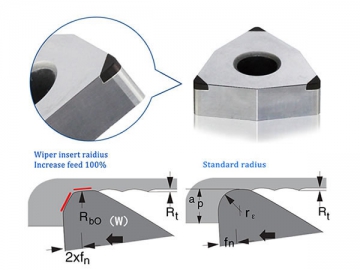

1. Uniquely designed wiping angle

2. The PCBN insert can improve the surface smoothness of processing material, and meet high surface roughness requirements

3. Highly welding strength

4. Bigger feed rate, higher cost performance

5. This tipped tool can improve the processing efficiency, and reduce the cost.

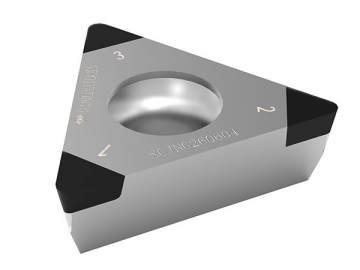

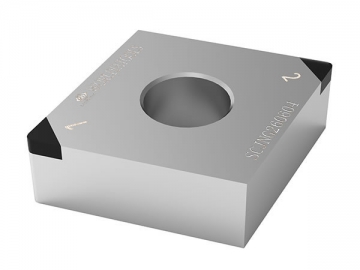

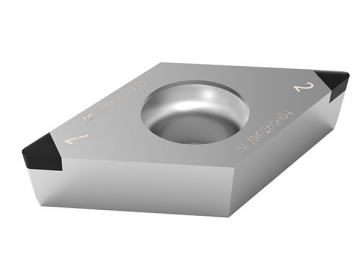

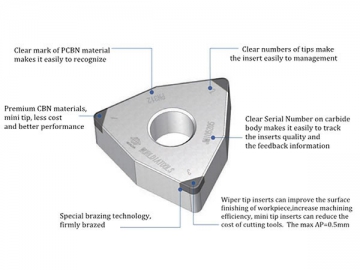

Worldia Wiper PCBN Insert:

1. Premium CBN materials, mini tip, less cost and better performance

2. Clear mark of PCBN material makes it easily to recognize

3. Clear numbers of tips make the insert easily to management

4. Special welding technology, firmly welded

5. Wiper tip inserts can improve the surface finishing of workpiece, increase machining efficiency, mini tip inserts can reduce the cost of cutting tools. The max. AP=0.5mm

6. Clear serial number on carbide substrate makes it easily to track the PCBN insert quality and the feedback information.

| Standard cutting edge | Sharp Cutting Edge | Strong Cutting Edge |

| S0102505 | S0051502 | S0103505 |

| Shape | ISO | ANSI | Cutting Edge | Tip Shape | Grade | Dimensions in mm | ||||||

| PN311 | PN310 | PN312 | ic | φd | s | r | la | |||||

| CCGW09T304-2N | CCGW3(2.5)1-2N | S0102505 | SLWG22S | ● | ● | ● | 9.525 | 4.4 | 3.97 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CCGW09T308-2N | CCGW3(2.5)2-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW070204-2N | DCGW2(1.5)1-2N | S0102505 | SLWG22S | ● | ● | ● | 6.350 | 2.8 | 2.38 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW070208-2N | DCGW2(1.5)2-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T304-2N | DCGW3(2.5)1-2N | S0102505 | SLWG22S | ● | ● | ● | 9.525 | 4.4 | 3.97 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T308-2N | DCGW3(2.5)2-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CNGA120404-2N | CNGA431-2N | S0102505 | SLWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CNGA120408-2N | CNGA432-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CNGA120404-4N | CNGA431-4N | S0102505 | SWWWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CNGA120408-4N | CNGA432-4N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DNGA150404-2N | DNGA431-2N | S0102505 | SLWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DNGA150408-2N | DNGA432-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DNGA150404-4N | DNGA431-4N | S0102505 | SWWWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DNGA150408-4N | DNGA432-4N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DNGA150604-2N | DNGA441-2N | S0102505 | SLWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DNGA150608-4N | DNGA442-4N | S0102505 | ● | ● | ● | 8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TNGA160404-3N | TNGA331-3N | S0102505 | SLWG22S | ● | ● | ● | 9.525 | 3.81 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TNGA160408-3N | TNGA332-3N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TNGA160404-6N | TNGA431-6N | S0102505 | SWWWG22S | ● | ● | ● | 9.525 | 3.81 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TNGA160408-6N | TNGA432-6N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| WNGA080404-3N | WNGA431-3N | S0102505 | SLWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| WNGA080408-3N | WNGA432-3N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| WNGA080404-6N | WNGA431-6N | S0102505 | SWWWG22S | ● | ● | ● | 12.70 | 5.16 | 4.76 | 0.4 | 2.2 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| WNGA080408-6N | WNGA432-6N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| SF | SL | SS | CB | CS | SWW | SWU |

| Full Face | Solid Tipped Corner | Solid CBN | Standard Tipped Corners | Standard Full Edge | Solid Tipped Corners Type ‘W’ | Solid Tipped Corners Type ‘U’ |

| ST | WG | CB |

| Nose Radius | Wiper | Chip Breaker |

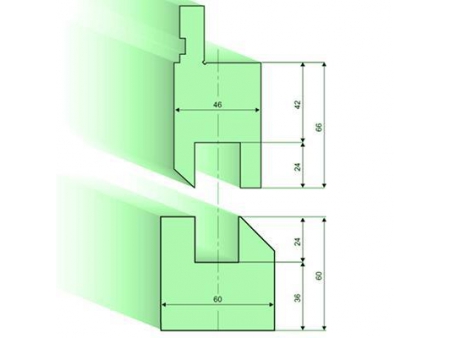

| Code | Ap | 22 | 25 | 28 | 30 | 40 |

| Size | Ap | 2.2 | 2.5 | 2.8 | 3 | 4 |

| Work piece Material | type | WORLDIA PCBN Grades | Content | PCBN Grade | Bond | Hardness | Characteristics | Applications |

| H | Solid tipped corners | PN311 | 45~50 | 1 | TiC | 2600~2800 | Good thermal stability and crater wear resistance | Used for high-speed continuous turning of hardened steel |

| PN310 | 60~65 | 1~2 | TiCN | 2600~2800 | Combination of wear resistance and thermal stability | Used for moderately interrupted and continuous turning of hardened steel | ||

| PN312 | 65~70 | 1< | TiN | 2700~2900 | High degree of toughness due to fine CBN and ceramic binder matrix | Used for heavy interrupted turning of hardened steel |

Material:

The tool bit uses premium PCBN blanks manufactured by world famous companies.

The body part uses high quality tungsten carbide.

Application:

Worldia PCBN wiper inserts are used for machining for gears, drive components and bearing components for individual series or mass production, especially for cast iron, hardened materials.

Packaging:

Our PCBN insert can be packed with standard WORLDIA packaging, and also various non-standard packaging as per request.

Quality Control:

We have dedicated team of quality control and precise equipment to keep good and stable performance for our products and processing services.

OEM/ODM Service:

We can customize the cutting tool and laser markings according to your requirements. Our business partners are all over the world including some cutting tool industry giants.

Contact:

We are ready to work together with friends from different walks of life to promote the development of super hard materials and tools industry, and also global agents are welcomed.

As a specialized PCBN insert manufacturer and supplier in China, Worldia also provides a wide range of products including diamond engraving tool, PCD saw blade, PCD diamond scribing wheel, and much more.