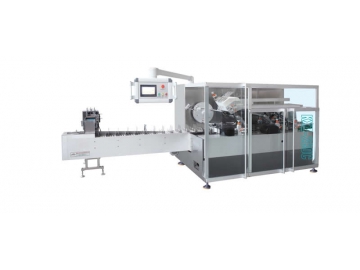

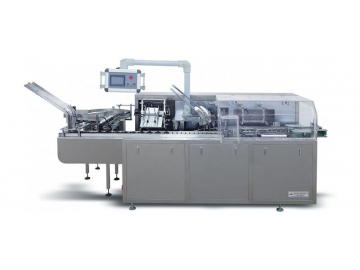

KXZ-130B Medium Speed Cartoning Machine

Description

With packing speed of 50-90 boxes/min, the KXZ-130B medium speed cartoner machine features higher working efficiency comparing with KXZ-130B packaging machine. The packing size is (70-250)mm×(50-130)mm×(20-80)mm, customized size is available. The medium speed cartoner machine is ideally suitable for packaging of auto parts and facial tissue.

Automatic Feeder-Customized

Product Loader

Carton Loader

Pusher Device-Fill Product into Caton Box

Carton Closed

Hot Melt Glue Sealing-Optional Function

| Packing speed | 30-80 cartons/min |

| Size of package | L(70-250)mm×W(50-130)mm×H(20-80)mm(Special size can be customized) |

| Cardboard requirements for packages | 250-450g/m² (up to the size of package) |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ |

| Air consumption | 20m³/h |

| Overall dimension | L4200mm×W1550mm×H1900mm |

| Weight | 1600Kg |

Main parts list

| Item | Name | Model and specification | Origin | QTY |

| 1. | PLC | CPIE-N30DT-D | Japan Omron | 1 |

| 2. | PLC Extended Module | CPIE-C1F11 | 1 | |

| 3. | Touch Screen | NB7W-TWOOB | 1 | |

| 4. | Inverter | 3G3JZ-A4015 | 1 | |

| 5. | Photoelectric Sensor | SICK 121 | SICK | 4 |

| 6. | Motor | CH-1500-10S 1.5KW | Taiwan CPG | 1 |

| 7. | Index Drive | 0S83-4L-180 | Zhejiang | 1 |

| 8. | Button | XB2 | France Schneider | 3 |

| 9. | Emergency Stop | ZB2 BC4D | 1 | |

| 10. | 5 relay | Zhejiang | 1 | |

| 11. | 8 transistor | 1 | ||

| 12. | Solenoid Valve | 4V210-08 | AirTAC | 2 |

| 13. | Air Filter/Regulator/ | BFR-2000 | 1 | |

| 14. | Proximity switch | TL-Q5MC1 | Japan Omron | 2 |

| 15. | Sucking disc | VF-30 | Korea | 2 |

| 16. | Vacuum Generator | ABM20-C | SMC | 1 |

| 17. | AC contactor | LC1E3210M5N | France Schneider | 1 |

| 18. | Switching power supply | PMC-24V 050V | DELTA | 1 |

| 19. | Air switch | 3P32A 1P10A | France Schneider | Each1 |

| 20. | Encoder | B-ZSP3806E2C | Japan Omron | 1 |

| 21. | Cover | Stainless Steel | Shanghai | 1 SET |

Hemp rope is all right while iron chain and wire rope should not be used. All the overhanging parts of the machine should be strapped by the rope, and the machine's surface must be protected by elastic items such as rubber or sponge. Solid board is needed to seal the whole machine firmly.

Installation

- This cartoning machine is a type of packaging equipment. It can be installed in rooms with good ventilation and adequate lighting.

- A spare distance of 1.5m is required around the machine for operation and maintenance.

- 380V-50HZ three-phase AC power supply and electrical grounding is necessary.

- It must be installed on a relatively flat ground. After installation, level of the machine should be checked by a gradienter. When it is not, you should adjust the four feet of the machine to keep it level.

- Every part should be checked if it is loose after being installed. Any mistake should be ruled out as soon as possible. To prevent rust, the machine is greased before being shipped. Thus, the excess grease on the surface should be cleaned before you run the machine. Cotton and alcohol is needed for the cleaning. After that, lubricating of certain parts is necessary.

Maintenance

- Keeping clean of the machine is necessary, and the rotating parts need to be cleaned and lubricated frequently.

- Cam structure and transmission chains should be lubricated every 15~40 hours. Motor oil of brand 50 is recommended (kinematic viscosity is around 47~53mm2/S50℃). Gear meshing parts should be lubricated every three months and Albany grease is recommended (ZG-1 or ZG-2).

- Cog belt and driving belt should not be contacted with grease, in order to lengthen its life span.

- To ensure regular and stable run of the machine, it should be shut down every three months to check the tension of the transmission chain and transmission parts. When it is necessary, you should adjust and fasten certain parts of it.

- Any breakdown of the machine should be carefully taken care of by professional mechanic. To avoid damage to any part of the machine, self dismantling is not allowed.