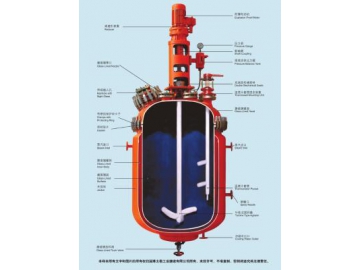

High Pressure Reactor

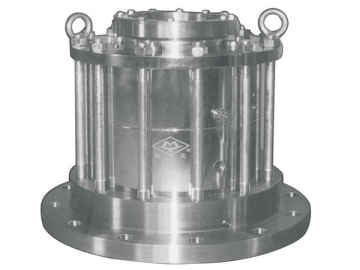

Adopting end face rare earth coupling drive, the high pressure reactor features static seal and no leakage. It completely solves the leakage problem of shaft sealing and is thus the ideal equipment for chemical reactions involving flammable, explosive and highly toxic substances. This equipment has been widely used in fuel, rubber, petroleum, chemical, pesticide, medicine, and other industries.

Kettle body of the high pressure reactor is mainly made of 1Cr18Ni9Ti stainless steel. According to the requirement of different media, titanium (TA2) sprayed with PTFE and lined with Ni can be made and used. Corrosion resistant stainless steel stirring bearing is adopted and the stirrer is suitable for the stirring of low viscosity materials rotating at high speed. There are upper discharging and lower discharging methods for customers to choose. With easy operation, stable running, small noise and other characteristics, this product is an ideal device for customers to conduct various chemical reactions.

Parameters

1. Design Pressure: 8.5Mpa

2. Design Temperature: 350℃

3. Working Pressure: 7.5Mpa

4. Working Temperature: 300℃

5. Hydraulic Test Pressure: 10.6Mpa

6. Material: 1Cr18Ni9Ti

7. Effective Volume: 2L

8. Heating Method: Electric heating, hot oil circulation heating, jacket steam heating

We are a high pressure reactor manufacturer and supplier in China. In addition to reactor, we also offer metallic nanometer powder, sand mill, bead mill system, bottom agitating mechanical seal, jet mill system, and much more.

Related Names

Pressurized Reactor | Autoclave