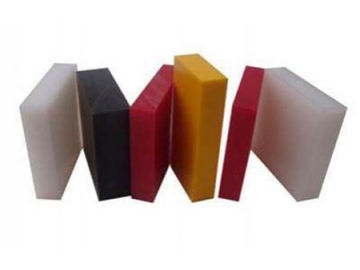

Ultra High Molecular Weight Polyethylene, UHMWPE Plate and Pipe

Introduction

UHMWPE plate and pipes are products made using an engineering plastic that features an outstanding performance at low temperatures. This material has an excellent shock resistance, and wear resistance, as well as great self-lubricating abilities. It has a very high molecular weight and features a better performance over ordinary polyethylene or other engineering plastics. Additionally, it has many features such as wear resistance, impact resistance, corrosion resistance, self-lubrication, shock absorption, low temperature resistance, non-toxic health, non-adhesion, water absorption, light weight, minimal surface tension, non-polarity and more.

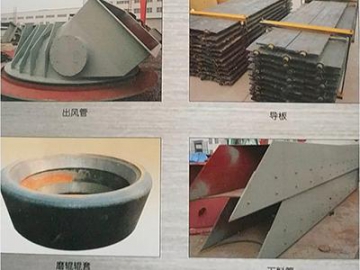

- Dredge pipes, coal gas pipes, nature gas pipes, marine industrial pipes, water pipes, oil pipes, ash pipes for coal-fired power plants.

- Various non-ferrous metal and black metal mine tailings pulp transportation pipelines, coal mine pulp transportation pipelines, food processing pipelines, chemical industry pipelines, food and beverage industry pipelines.

- Injection molding for various mechanical components: various assembly line wear- resistant components such as food processing machinery, printing and dying machinery, packaging machinery, belt conveyor idlers, low temperature resistance parts in frozen machinery and the nuclear industry, auto parts and more

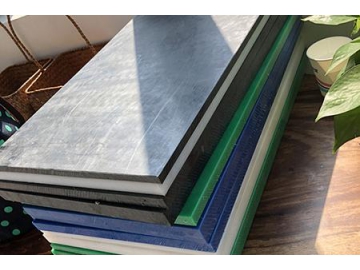

- Liner plate for bulk carriers, cement bins, coal bins and mining cars.

- Pipe formation through extrusion processing to cover submarine cables or optical cables.

- It can be hollow blown into various shapes for chemical liquid containers and beer, wine bottles, as well as automobile and motorcycle fuel tanks and more.

1. Wear resistance comparison (%)

| Materials | Our product | PTFE | Nylon 6 | A3 steel | POM | Copper |

| Wear rate | < 0.1 | 1.72 | 3.3 | 7.36 | 1.5 | 13.12 |

| Materials | Our product | PTFE | Nylon 6 | PC | ABS | A3steel | 45#steel |

| Impact strength | 100-160 | 1.6~15 | 16 | 60-110 | 5-40 | 700 | 300~400 |

| Materials | LDPE | Cross-liking LDPE | HDPE | Cross-liking HDPE | Our product |

| cracking resistance of environmental stress (ASTM-1693) | 2 | ≥500 | 9 | ≥500 | > 4000 |

| Materials | Our product | Ice -ice | PA66 | Glass -glass | Steel-steel | Glass -metal |

| Friction coefficient | 0.05~0.15 | 0.50 ~15 | 0.37 | 0.9~1 | 0.58 | 0.5~0.7 |

| Items | ASTM | unit | Our product | HIPS | NylonPA66 | PC | POM | PTFE |

| Density | D1505 | g/m3 | 0.95 | 1.03~1.04 | 1.13-1.15 | 1.2 | 1.41 | 2.14-2.2 |

| Impact strength | D250 | Kg/cm/cm | >140will not break | 16~44 | 6~11 | 71. ~95 | 8~13 | 16 |

| Elongation at break | D638 | % | 350 | 5~60 | 60~300 | 100~130 | 75 | 200~400 |

| Friction coefficient | D1894 | 0.07~0.11 | 0.38 | 0.37 | 0.36 | 0.18 | 0.04~0.2 | |

| Wear rate | D1175 | Mg/1000 | 70 | 770 | 175 | 280 | 210 | 250 |

| Water absorption ratio | D1505 | % | < 0.01 | 0.02~0.45 | 1.5 | 0.15 | 0.25 | > 0.01 |

| Breakdown voltage | D149 | KV/mm | 50 | 14-20 | 15-19 | 16 | 15 | 20 |

- The wear resistance of UHMW-PE is 8-10 times higher than steel and 27 times higher than brass.

- It has an excellent impact-resistance, which is 5 times better than ABS and 10 times better than nylon.

- It has an excellent low temperature resistance, which maintains the impact resistance and wear resistance in -196℃ (liquid nitrogen) and -269℃ (liquid nitrogen)

- It has no electrochemical action and no scaling.

- It has an extremely low friction coefficient, excellent self-lubrication and it will not absorb water.

- Its specific gravity is 0.95.

- It is non-toxic

- It is convenient to process.

- It has an excellent corrosion resistance.

Related products

Send Message

Most Recent

More

Other Products

Videos