Continuous screen changer with Backflush System

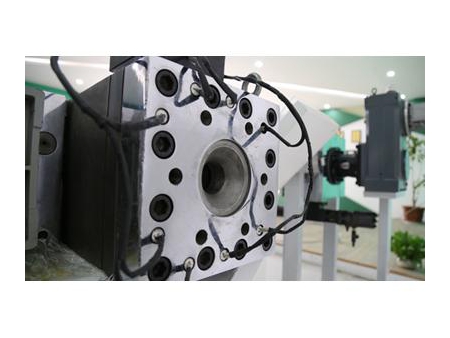

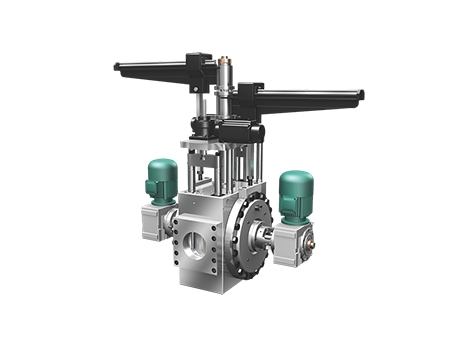

The continuous melt filtration screen changer will automatically control the servo motor to automatically rotate, exhaust, and feed. Continuous production is possible without turning off the machine to change the screen, thus avoiding down time, and improves the production efficiency. The continuous melt filter is often used in film blowing machines, wire drawing machines, tube extruders, and other plastic extrusion equipment.

In the plastic granulation and extrusion industry, melt filters are a large part of a continuous rotary extrusion system, and are also key to determining the quality of granule products. Leeny’s melt filters can be installed into a broad range of extrusion systems, such as plastic granulators, aluminum plastic plate extruders, XPS extruders, film faced plywood extruding machines and more.

Suitable plasticsThe continuous melt filtration screen changer is suitable for PP, PE, PS, PA, PVC, PC, PET and other plastics.

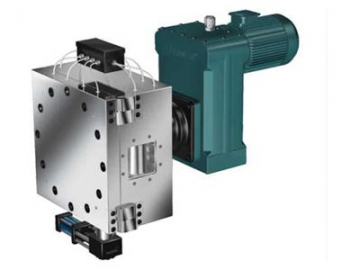

3D model diagram| Items | Suitable Output (kg/h) | Dimension | Filter Size | Screen Changer Weight (kg) | Heating Power | ||||

| Ll(mm) | L2(mm) | L3(mm) | Diameter (mm) | Area (cm2) | Voltage (V) | Power(KW) | |||

| LN-Φ45-90 | 100-250 | 220 | 220 | 280 | Φ100 | 78 | 138 | 220/380 | 4.5/6.8 |

| LN-Φ100-150 | 300-500 | 270 | 270 | 330 | Φ150 | 176 | 280 | 220/380 | 6.5/8.6 |

| LN-Φ160-200 | 600-1200 | 320 | 320 | 380 | Φ200 | 314 | 370 | 220/380 | 8.5/1.07 |

| LN-Φ210-250 | 800-2000 | 370 | 370 | 400 | Φ250 | 490 | 450 | 220/380 | 9.5/1.17 |

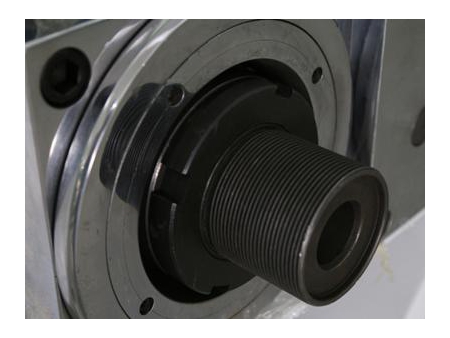

- Filter body: die steel P20, high strength, high temperature resistance, not easy to deform or break, easy to repair and maintain.

- Filter screen: common mesh.

- Servo motor: Inovance.

- Gear box: with hard gear surface and grinding gear, high strength and barely no noise.

- PLC control system: Schneider or Siemens contactor, Inovance servo control motor, Inovance controller, Siemens or Mitsubishi PLC control system.

- Touch panel: Taiwan’s brand.

- No material leakage even under high pressure.

- During screen replacement, servo motor can be controlled to automatically rotate, exhaust or feed.

- Widely application in various extrusion systems, such as film blowing machine, wire drawing machine, packing strap machine, lamination machine, tube extruder, sheet extruder, bottle blowing machine, granulator, chemical fiber spinning machine, etc.