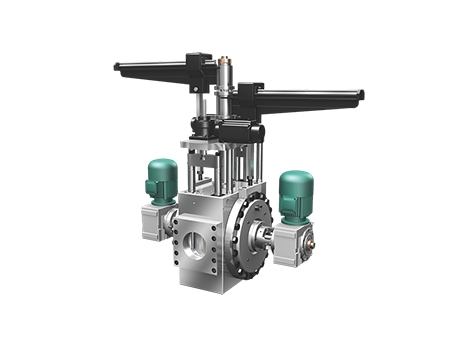

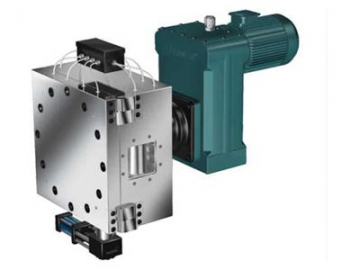

Hydraulic Screen Changer, Single Piston Screen Changer

The hydraulic screen changer is a filter system used for handling new materials or recycling materials. A conventional melt filter requires that a machine be shut down to change the screen, which influences the filtration quality. To avoid having to do that, Leeny researched and developed the hydraulic screen changer, which does not require the machine to be turned off for screen changing, and screen changing can be done extremely quickly.

In the plastic granulation and extrusion industry, melt filters are a large part of a continuous rotary extrusion system, and are also key to determining the quality of granule products. Leeny’s melt filters can be installed in a broad range of extrusion systems, such as plastic granulators, aluminum plastic plate extruders, XPS extruders, film faced plywood extruding machines and more.

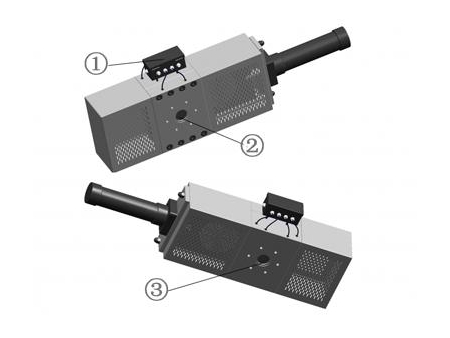

3D model diagram

- ①temperature control junction box

- ②feeding inlet

- ③venting outlet

| Items | Suitable Output(kg/h) | Dimension | Filter Size | Screen Changer Weight (kg) | Heating Power | ||||

| Ll(mm) | L2(mm) | L3(mm) | Diameter(mm) | Area(cm2) | Voltage(V) | Power(KW) | |||

| LN-SSP-150 | 300-500 | 235 | 150 | 990 | Φ150 | 176 | 280 | 220/380 | 6.5/8.6 |

| LN-SSP-200 | 600-1200 | 280 | 180 | 1155 | Φ200 | 314 | 370 | 220/380 | 8.5/10.7 |

| LN-SSP-250 | 800-2000 | 300 | 225 | 1260 | Φ250 | 490 | 450 | 220/380 | 9.5/11.7 |

| LN-SSP-300 | 1000-2500 | 380 | 300 | 1400 | Φ300 | 706 | 600 | 220/380 | 13.0/18.0 |

- The sliding orifice plate material is 38CrOMaLA. After a nitrogen treatment, the surface hardness is 60° HRC or more.

- Filter body: die steel P20, high strength, high temperature resistance, not easy to become deformed and broken.

- The self-tightening block is processed from vacuum quench treatment, featuring high wear resistance and above 60° HRC.