Metal Oxide Process Formaldehyde Plant

Request a Quote

The metal oxide process is a formaldehyde manufacturing process that uses iron molybdate as the catalyst. Helipont offers two reactor heat carrier types: a heat transfer oil and a molten salt.

Flow chart

Main Formaldehyde Manufacturing Equipment

- Methanol pre-evaporator

- Absorption tower

Advantages

- Less formaldehyde consumption

- Longer catalyst work period

- Formaldehyde concentration can reach 50%, while methanol content is less than 0.5%.

Formaldehyde Production Process

- Send compressed air to the methanol pre-evaporator.

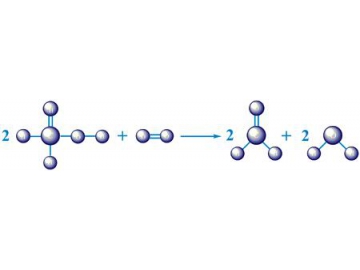

- Send gaseous methanol and air through the reactor that contains the catalyst for a reaction.

- Condense the formaldehyde gas from the reactor into a formaldehyde liquid.

Annotation: For more information on our production processes, please do not hesitate to contact us.

Raw material specification

| Type | Index |

| Formaldehyde,Wt% | 37-57 |

| Based on 37%, | |

| Methanol,Wt% | < 0.8 |

| Formic acid,Wt% | < 0.03 |

| Consumption | |

| Methanol | 93% |

| Methanol,kg/MT* | 425 |

| Electricity (IBL),kW/MT* | 72 |

| CW - 10 deg C rise,m3/MT* | 50 |

| Steam consumed,kg/MT* | 0 (Net. prod.) |

| Steam output,kg/MT | 800undefined(1.2~2.0Mpa) |

Comparison of two process

Compare the metal oxide process and silver catalyst process on the economic front (assume 100,000 tons).

- Equipment: The metal oxide process requires a larger upfront investment in order to produce the same 55% formaldehyde solution.

- Steam output: metal oxide process, 800 kg/MT(2.0Mpa), while silver catalyst process 550 kg/MT(0.6Mpa). Assuming the steam unit price is $22/ton, metal oxide processes save $550,000/year.

- Methanol consumption: metal oxide processes save 20kg/TPA of methanol. Assuming the unit price of methanol is $430/t, metal oxide processes save $860,000/year.

- Service life of the metal oxide processing equipment is more than 50 years, which is almost 3 times longer than equipment used in the silver catalyst process. This means that using the metal oxide process saves up to $15,000/year in operation costs.

- Catalyst cost: The metal oxide process costs $260,000/year, while silver regeneration costs $20,000/year. Thus, the silver regeneration process costs $240,000 less per year

- Power consumption cost: metal oxide processes are higher than a silver catalyst process by about $440,000/year. (metal oxide process 70kwh/t, silver catalyst process 26kwh/t, electricity unit price $0.1/kwh)

- Using the metal oxide process saves about $740,000/year.

Projects Were Work on