G-1325 CO2 Laser Cutting and Engraving Machine

Laser Cutting and Engraving Machine / Laser Processing Machine / CO2 Laser Engraving Machine

The G series CO2 laser cutting and engraving machine offers high precision and large format cutting solutions for acrylics, wood, cardboard and other materials.

Models and Tech Specs| Model | ||

| Working Area | 49" x 98" / 1250 x 2500mm | |

| X-Y Maximum Simultaneous Positioning Speed | 30m/min | |

| Positioning Accuracy | ±0.05mm/m | |

| Repeatability | 0.03mm | |

| Machine Weight | 1000Kg | |

| Machine Size (W x L x H) | 2215mm x 4030mm x 1205mm | |

| Laser Source | Glass CO2 Laser | Metal Packaged, Dual Glass Tube Combined Laser |

| Wattage | 130W/150W | 260W |

Main Configurations Introduction

Large Format Working Area

The G-1235 laser cutting and engraving machine has a working area of 49" x 98" (1250mm x 2500mm) in an X-Y dimension. With an aluminum strip table, users can cut hard and inflammable materials such as acrylic, cardboard and wood. The strips are separate and removable, so that uses can remove them as needed based on material in order to avoid laser reflection and get a clean cutting edge. The G series features a high strength body, and uses the most popular steel pipe welding structure in order to ensure the high speed, high precision and long-term stable operation.

Open Architecture and Dual Direction Material Loading

The G series laser cutting machines use an open architecture to ensure easy loading and unloading of large workpieces. Users can load the work pieces from front to back or left to right and can pick up processed parts on every corner of the table with ease.

Deep Collecting Bay and Picking Up Drawer

After processing, small parts and parts without a supporting strip under them will drop into the collection bay to avoid interacting with the laser. Users can retrieve them simply by pulling out the drawer.

High precision Ball Screw Motion System

Unlike a low rigidity belt motion system, the G series is equipped with a high precision ball screw motion system with a much higher response rate. Users will find less shape distortions in the same motion control settings, especially in cases such as a small circle, fast turn or sharp corner. There is no vibration or resonance from the belt, which leads to no adverse effects on the cutting edge roughness.

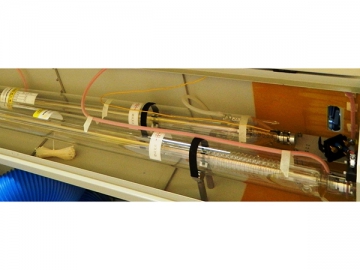

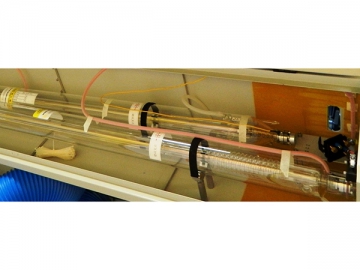

Laser Source with Great Cost Performance Ratio

The G series laser equipment can be equipped with a 130W or 150W glass CO2 laser tube. The 150W laser can cut acrylic up to 1.1-/8' thick (30mm) making it the best on the market.

If users seek to do a lot of cutting on very thick material and want to be more productive, we recommended our metal packaged, dual glass tube combined with a 260W CO2 laser. Users will get more done without sacrificing the processing quality.

Industrial Chiller

The G series laser is equipped with a high quality industrial chiller to ensure the continuous and stable output of the laser.

Laser Head

The G series laser cutting and engraving machine can be equipped with a single or dual heads according to laser configurations. Users can easily adjust the space between the two heads.

Our laser head has 2 installation positions for the focus lens, with the same focusing space between the nozzle and the workpiece. The lower position if for 2", ideal for customers who need an extremely thin cutting slit. The upper position is 4", ideal for general purpose cutting. The reflection mirror adjustment is designed to be stable and easy to use. With 3 adjustment screws, it is easy to align in any condition.

The laser engraving machine is also equipped with an air assist assembly with a flow adjustment on the laser head. By directing a steady stream of compressed air across the cutting surface, the possibility of flaming, scorching or charring is reduced when cutting materials such as acrylic or wood.

High Quality Optics

Our G series laser engraving machines are equipped with optics produced in America in order to produce a high quality and consistent laser beam across the entire working area. This achieves a better cutting and engraving quality.

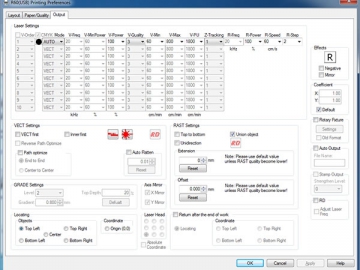

Visual Control System

This series of laser cutting and engraving machines is equipped with a high performance control system featuring a user friendly visual UI panel. By embedding flash storage in the controller, users can transfer jobs through a USB drive, Ethernet, or flash disk, then finish the processing offline without relying on a computer connection. With a true color TFT LCD panel, users can also preview machine status and job details before processing, such as the current position of the laser head, connection status, graphic detail, processing parameters and estimated processing time. Users can also adjust the parameters for different materials, as well as run a processing simulation on the panel. The control system will save all changes made for future use. While processing, users will receive real time processing information on the panel, and can adjust parameters on the fly according to actual results. In the event of power failure or mistakes, users can recover the job.

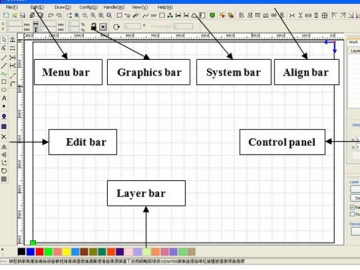

Software and Print Driver

Uses can import or create a new design, finish layout and sorting, run a processing simulation and directly control the machine using our software.

With the user friendly print driver, users can also use their favorite applications, such as CorelDRAW, Photoshop, or AutoCAD to transfer a job to the machine through a few simple clicks.

With layers and a color mapping function, users can assign different processing parameters for different colors in a design. There is no need to run separate jobs for one project, and processing is faster with a more precise laser control.

Exhaust Blower

We provide a ready to use laser cutting and engraving machine package with all necessary parts, including the exhaust blower. Simply set up the machine and start the project.

Safety and Reliability

The G series is designed, engineered and built with safety and reliability in mind. We use electronic parts from internationally known suppliers and build a system to meet international standards. There are numerous sensors around the machine, such as an open door sensor, open laser tube box sensors, laser cooling water pressure sensor and more. The machine will stop automatically if something unsafe occurs. When this happens, users must shut down the machine immediately and completely by pressing the easy to reach emergency stop button on the panel.

Applications