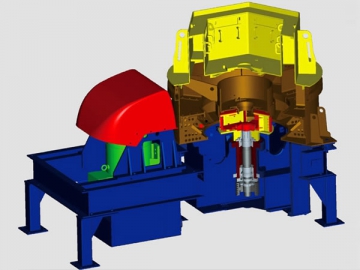

Single Cylinder Hydraulic Cone Crusher

Product Brief Introduction

Ormaise® RC series single cylinder hydraulic cone crushers are patented hydraulic crushing machines widely applied in a variety of industries. The powerful portable crushers can be used for the intermediate and fine crushing of all kinds of materials, such as iron ore, non-ferrous metal ores, granite, limestone, quartzite, and sandstone. This series of single-cylinder hydraulic cone crusher uses a combination of high quality crushing machinery parts and has automatic hydraulic and electric intelligent control technology.

To meet individual demands, we can supply single cylinder cone crushers with power between 160 and 335kw, for crushing materials with size from 60 to 450mm.

Product Features

- Transmission shaft assembly for RC series

- Hydraulic cylinder assembly for RC65

- Spindle for RC50

- Electric motor

- Controller

- Rack being machined

1. Designed using advanced CAD technology, the single cylinder hydraulic cone crusher features a large-diameter, heavy-duty main shaft and high strength mainframe that make the device more sturdy and durable.

2. The mining equipment uses heavy-duty bearings to replace traditional copper sleeve models. It has reduced the clearance and increased the swing speed of the main shaft that increase output and improve grain consistency.

3. The hydraulic control system adjusts the discharge opening and provides more reliable overload protection.

4. The stone crushing machinery can change the stroke according to the material properties and meet different crushing demands.

5. The advanced automatic control system improves the quality of the end product and maintains maximum crushing efficiency within a safe range.

6. A variety of crushing cavities are available for each model.

7. The upper rack is divided into two parts-an arm support and a crushing bearing seat. It can be separated for easy maintenance.

8. The application of the spiral bevel gear drive increases the carrying capacity and makes operation more stable.

9. The structure of the entire single cylinder hydraulic cone crusher is simple and easy to operate, which has greatly reduced the maintenance time for workers

Technical Parameters of the Single Cylinder Hydraulic Cone Crusher

| Model | Feed opening size (mm) | Power (kw) | Close-edge discharging opening size (mm) | Weight (kg) | ||||||||||

| Capacity (t/h) | ||||||||||||||

| 12 | 14 | 16 | 18 | 20 | 22 | 25 | 30 | 35 | 40 | 50 | ||||

| | 90 | 200 | 95-120 | 100-125 | 110-130 | 120-145 | 125-150 | 21000 | ||||||

| 115 | 200 | 110-130 | 120-150 | 130-160 | 140-170 | 155-185 | 170-200 | |||||||

| 150 | 200 | 140-170 | 150-180 | 160-190 | 170-200 | 180-210 | 190-220 | 200-230 | ||||||

| 220 | 200 | 180-210 | 190-220 | 210-240 | 230-270 | 265-310 | 300-330 | 320-360 | ||||||

| 250 | 200 | 200-300 | 220-250 | 240-280 | 275-320 | 310-340 | 330-370 | 360-400 | ||||||

| 110 | 250 | 175-205 | 195-235 | 210-250 | 225-265 | 240-280 | 255-295 | 270-310 | 23500 | |||||

| 150 | 250 | 265-305 | 290-330 | 305-350 | 320-360 | 335-375 | ||||||||

| 220 | 315 | 285-355 | 295-365 | 305-375 | 320-400 | |||||||||

| 250 | 315 | 320-400 | 330-430 | 355-455 | 380-480 | |||||||||

| 340 | 315 | 370-470 | 395-495 | 420-520 | 460-560 | |||||||||

| 150 | 335 | 300-370 | 350-410 | 370-430 | 390-450 | 410-470 | 46000 | |||||||

| 225 | 335 | 420-520 | 470-570 | 520-620 | ||||||||||

| 450 | 335 | 540-620 | 560-670 | 600-700 | 650-750 | |||||||||