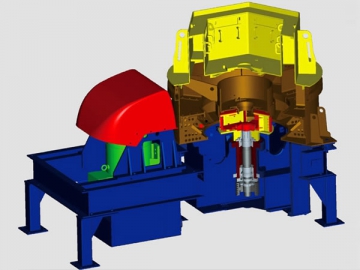

Multi-Cylinder Hydraulic Cone Crusher

Product Brief Introduction

The multi-cylinder hydraulic cone crusher is an evolved version of standard spring cone crushers. The main difference between the multi-cylinder hydraulic cone crusher and spring cone crusher is the actuation mechanism. The hydraulic cone crusher can operate automatically due to its hydraulic actuation.

We can offer four models of hydraulic cone crushers for customers to choose from. The max. feeding material size can be 40mm, and thus the crushing equipment can meet varied material crushing demands.

The multi-cylinder mining cone crusher is widely used in the fields of metallurgy, construction, hydroelectric projects, transportation, and chemical industries for crushing all sorts of hard materials. They are suitable for the primary crushing of many kinds of rock such as ores, concrete, fireproof materials, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc.

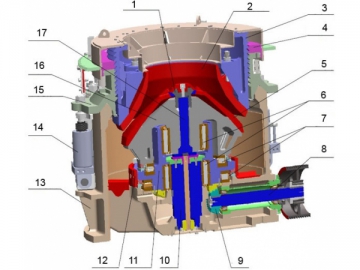

Internal Structure of the Multi-cylinder Hydraulic Cone Crusher

1. Fastening nut

2. Lining plate for the fixed cone

3. Adjustment ring for the fixed cone

4. Hold-down ring

5. Lining plate for the movable cone

6. Cylindrical roller bearing

7. Large diameter thrust bearing

8. Drive shaft

9. Gear

10. Spindle

11. Eccentric shaft

12. Balancing weight

13. Lower machine frame

14. Hydraulic cylinder

15. Support ring for the fixed cone

16. Movable cone

17. Movable cone spindle

Product Features

1. The multi-cylinder hydraulic cone crusher's advanced crushing chamber design enhances the uniformity of crushed materials.

2. Various speed and cavity settings can crush more material and reduce energy consumption.

3. A full rolling bearing design is used to increase horsepower, which leads to a greater crushing force, decreases friction, and produces high yields

4. Large diameter thrust bearings are adopted to improve bearing capacity, which is more suited for hard metal ore mining.

5. The heavy-duty manganese steel can endure harsh working conditions and the extend service life of the crusher.

6. An advanced hydraulic control system is employed by the hydraulic cone crusher. The discharging port is convenient to operate and reliable overload protection is provided.

7. A backstop is adopted to prevent the rotation of the dynamic cone when not in operation to reduce extra wear.

8. Different degrees of crushing can be realized with a quick cleading change.

Main Technical Parameters of the Multi-cylinder Hydraulic Cone Crusher

| Model | Max. feeding size (mm) | Power (kW) | Tight-edge discharge opening size (mm) | Weight (kg) | |||||||||

| Processing capacity (TPH) | |||||||||||||

| 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||||

| 275 | 200 | 120-150 | 150-190 | 190-250 | 230-300 | 210-275 | 230-300 | 260-335 | 305-390 | 355-445 | 440-490 | 16600 | |

| 325 | 280 | 135-170 | 180-225 | 220-260 | 240-290 | 260-310 | 275-335 | 295-380 | 350-445 | 405-510 | 500-560 | 21000 | |

| 375 | 315 | 150-200 | 200-260 | 245-315 | 275-360 | 300-385 | 320-415 | 355-450 | 390-500 | 445-575 | 505-645 | 24900 | |

| 400 | 400 | 200-250 | 260-330 | 315-395 | 360-450 | 385-485 | 405-510 | 450-565 | 450-620 | 565-715 | 645-810 | 31000 | |