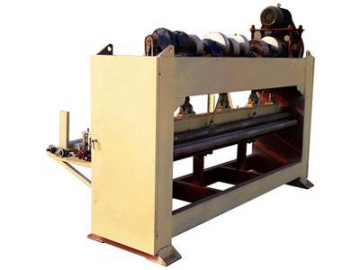

Low Speed Needle Loom

Needle punching machine is used to punch in the fiber web continuously to make the fibers directly tangle each other together. By this means, the strength of fiber web can be increased. The needle punching machine we manufactured is equipped with fuel injection pump which can automatically inject the fuel, leading to stable running of piston motion and prolonged service life. This needle punching machine is mainly used for the production of nonwovens, such as needle punch, mattress, insulation blanket for greenhouse, etc.

- Width of products: 2.2m

- Thickness of products: 2~10mm

- Output Speed: 7~8m/min

- Weight: 100g/m2-1000g/m2

- Needling Frequency: 0~500 times/min

- Needle travel: 35~65mm

- Number of Needle: 2000-6000s/m

- Power:9kw

- Size: 3000*1000*2200mm

- Weight: 2000kgs

The roller is mainly used to compress the fibers when transporting the fibers to needle punching machine. The efficiency of needle punching machine for compact fiber is higher.

Hoops: Hoops are mainly used to fix the fibers. Hoops are needed to use when the weight of raw materials are relatively high to compact the raw materials from last process and increase needle punching efficiency.

The needle plate of the needle punching machine we manufactured is easy to replace. Therefore, it is convenient for clients to replace broken needle, leading to time saving.

- Before Processing

- After Processing