Basic info:

Max speed: 80m/min

Accurate registration levels: ± 1mm

Sheet sizes: 400 mm -1650 mm

Top sheets thickness: 150-800 g/m22

Bottom sheet thickness:0.5-10mm2

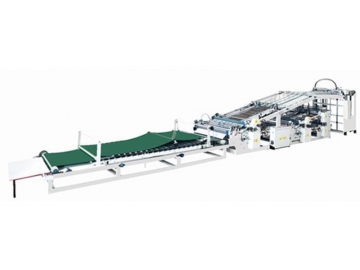

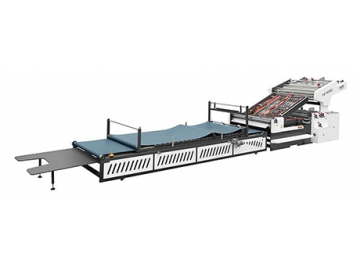

This automatic 5ply flute sheet to sheet laminating(mounting) machinedesigned for printed cardboard and corrugated paper laminating. The equipment is made up of 3 automatic feeding parts (top sheet feeder and 2 corrugated paper feeding component), two gluing parts, two laminating parts, and a pressing conveyor. The equipment is suitable for the laminating of printing paper to corrugated paper of AA flute, AB flute, AE flute, BA flute, BB flute, BE flute, EA flute, EB flute, EE flute, and corrugated paper can be changed as needed. It can also be applied to laminate cardboard to single flute to make 3 ply sheet as well as for the lamination of corrugated to corrugated to make 4 ply corrugated paper. This is an excellent machine for printing operations, providing good accuracy and quick operation, maximizing efficiency.

| Model | YB-1450E | YB-1650E |

| Max sheet size | 1450*1100mm | 1650*1100mm |

| Min sheet size | 400*400mm | 400*400mm |

| Top sheet thickness | 150-800GSM | 150-800GSM |

| Bottom sheet thickness | 0.5-10mm | |

| Max speed( sheets/hour) | 80/min | 80/min |

| Fitting precision | ±1mm | ±1mm |

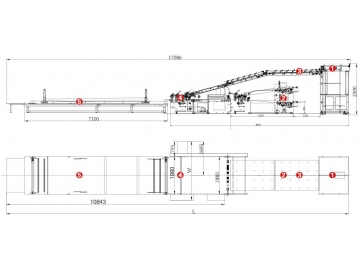

| Dimensions | 15.1*2.45*2.6M | 15.1*2.65*2.6M |

| Machine weight | 8800kgs | 9800kgs |

| Machine power | 28HP/380V | 30HP/380V |

-

Top Feeder (For Cardboard)

It is equipped with four sets of foreheading suckers which ensure smooth feeding, two sets of picking suckers, emergency stop control for double sheet, a missed sheet or misaligned sheet and an alarm for errors. -

Corrugated Paper (Middle and Lower) Feeder

1)Controls either of the corrugated feeding parts or both of them to feed sheet.

2)Single corrugated bottom feeding with strong suction power pump

3)It is equipped with 14 sucking belts (7 for each), which guarantees strong suction and smooth feeding. Paper Collector

Moving in line on the edge of the sheet, the machine operates with great elasticity with smoothness and stability. Equipped with 20 gauges(8 on the front and 12 on the back), it is driven by the left and right chains with a bite type moving forward, pushing the paper with high accuracy.

The moving of the top and bottom sheet is controlled by the “relative position controller”. It can adjust the size accurately within ±1.5mm.-

Laminating Part

The front laminating part can handle AA flute, AB flute, AE flute, BA flute, BB flute, BE flute, EA flute, EB flute, and EE flute. The laminated flute can exchange to each other and laminate the cardboard to one flute. Normally the speed is 0-80sheet/min. The glue part is made up of 4 rollers: the upper ones are a glue roller and metering roller; the lower is a pressure roller. The metering roller can control the density of the glue on the corrugated paper and is controlled by the pressure roller.