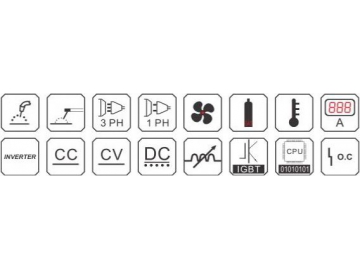

MIG MMA Welding Machine, IGBT Inverter Welder

Main Parameters

Applicable Welding Wire Diameter: 0.6/0.8/0.9/1.0/1.2mm (MIG mode), 1.6-5mm (MMA mode)

Applicable Power Supply: Single Phase/Three phase

Rated Input Voltage: 110V/220V/380V

Rated Input Power: 3.3kW-12kW

Rated Input Current: 15.3A-58.4A

Open Circuit Voltage: 55V/60V/61V

Protection Class: IP23

Insulation Class: H

Cooling System: Forced air cooling

Our MIG200/250/280/315GW series IGBT inverter MIG welding machine is designed with an exposed wire reel, thus ensuring an easy operation. It also features high welding efficiency, energy conservation and great durability. The welding machine can work in MMA welding mode or MIG welding mode. It is often applied for welding carbon steel, ordinary low alloy steel and stainless steel.

Features- The ability to continuously carry out loading at a high frequency allows the MIG welding machine to better accommodate industrial applications.

- The welding machine features an excellent dust prevention, water resistance, and corrosion resistance and protection class of IP23, significantly enhancing the machine service life.

- When the working voltage or current is too high or the welding machine is over heated, the overheat protection, overcurrent protection and low voltage protection features will be automatically used, thus ensuring operation safety.

- Both regular 2T and semi-automatic 4T modes are supported, accommodating different operating habits. In 2T mode, the operator will need to hold the switch down during the entire cutting process. Once the switch is released, cutting stops. In 4T mode, the operator simply needs to toggle the switch on, let go and then cut and toggle it off when finished.

- In MMA welding mode, a LIFT TIG contact type arc striking is used. The arc striking is done through direct contact between the tungsten electrode and the workpiece, resulting in a short circuit. As a result, the arc will be easily struck, resulting in a soft arc.

- Welding parameters such as current and voltage will be visually displayed on the digital panel, where they can also be adjusted.

| Model | MIG200GW-1 | MIG200GW-2 | MIG250GW | MIG280GW | MIG315GW | |||||

| Wire Diameter | 0.6/0.8/0.9mm | 1.6-3.2mm | 0.6/0.8/0.9mm | 1.6-4mm | 0.8/0.9/1.0mm | 1.6-4mm | 0.8/1.0/1.2mm | 1.6-5mm | 0.8/1.0/1.2mm | 1.6-5mm |

| Rated Input Voltage | 1P 110V | 1P 220V | 1P 220V | 3P 380V | 3P 380V | |||||

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | |||||

| Welding Mode | MIG | MMA | MIG | MMA | MIG | MMA | MIG | MMA | MIG | MMA |

| Rated Input Power | 3.3KW | 3.7KW | 6KW | 5.3KW | 8.3KW | 9.4KW | 9.2KW | 10.3KW | 11KW | 12KW |

| Rated Input Current | 41.5A | 46A | 37.4A | 33A | 51.6A | 58.4A | 15.3A | 17A | 18A | 20A |

| Welding Current Range | 40-130A | 40-120A | 40-200A | 40-160A | 40-250A | 50-280A | 50-315A | 50-300A | ||

| Welding Voltage Range | 15-30V | 15-30V | 14-28V | 14-30V | 14-32V | |||||

| Duty Cycle (25°C 10min) | 60%130A, 100%100A | 60%120A, 100%90A | 60%200A 100%155A | 60%160A 100%124A | 60%250A, 100%194A | 60%280A, 100%217A | 60%315A, 100%244A | 60%300A, 100%232A | ||

| Open Circuit Voltage | 55V | 61V | 60V | 60V | ||||||

| Efficiency | ≥80% | ≥80% | ≥80% | ≥85% | ≥85% | |||||

| Power Factor | 0.73 | 0.73 | 0.73 | 0.93 | 0.93 | |||||

| Protection Class | Ip23 | Ip23 | Ip23 | Ip23 | Ip23 | |||||

| Insulation Class | H | H | H | H | H | |||||

| Cooling System | AF | AF | AF | AF | AF | |||||

| N.W | 21KG | 21KG | 25KG | 25.5KG | 25.5KG | |||||

| G.W. | 28KG | 28KG | 31.5KG | 32.0KG | 32.0KG | |||||

| Packing Dimension | 705×325×490mm | 705×325×490mm | 675×355×725mm | 675×355×725mm | 675×355×725mm | |||||

Customization

The appearance, welding current, product manuals and package of our MIG welding machine can be customized according to customer requirements.

- Electrode Holder

- Earth Clamp

- Mask

- Hammer Brush

- PU Tubing

- Wrench