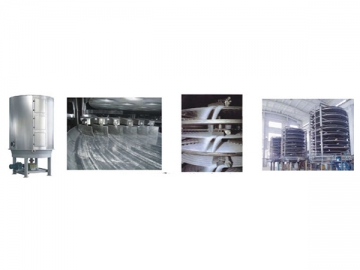

Vacuum Harrow Dryer

Description:

Vacuum harrow dryer is mainly used for drying explosive material, material easy to be oxidized, and paste material.In the vacuum condition, boiling point of the solvent is decreased,and air is isolated, it avoid the material from being oxidized and deterioration. Input heating medium (hot water, hot oil) into the jacket, and feed damp material into the drying chamber.Harrow-teethed shaft stirs the material to make the heating be uniform. When achieving the drying requirements, open the discharging valve at the bottom of the chamber, under the stirring action of the harrow teeth, material moves to the middle and discharged.

Features:

1. Being adapted the big area heating way, its heat conducting area is large and its heat efficiency is high.

2. Being installed stirrer in the machine, it makes raw material in cylinder form the state of continuous circle inside the cylinder, so the uniformity for raw material’s being heated is raised greatly.

3. Evaporation intensity is high, in general it can evaporate10~15 kg (water)/m2.h.

4. The powder in solvent vapor is filtered by the bag filter, there is no environmental and product recovery ratio is high.

5. Being installed stirring device in the machine, pulpiness, paste-like mixture or powder raw materials can be dried easily.

Working Principle:

It is an innovation horizontal batch-type vacuum dryer. The moister of wet material will be evaporated by heat transmission. The stirrer with squeegee will remove material on hot surface and move in the container to form cycle flow. The evaporated moisture will be pumped by vacuum pump.

Scope of Application for Vacuum Rake Type Dryer:

The following raw materials from pharmaceutical industry, foodstuff industry, chemical industry and so on can be dried.

Suitable for pulpiness, paste-like mixture or powder raw material.

Thermal sensitive raw material having the requirement to dry at lower temperature.

Raw materials that are easy to oxidize or explode and have strong irritative or toxic.

Raw materials that need to recover solvent.

| Item | Model | |||||||

| Name | Unit | ZP-50G0 | ZPG-750 | ZPG-1000 | ZPG-1500 | ZPG-2000 | ZPG-3000 | ZPG-5000 |

| Working volume | L | 300 | 450 | 600 | 900 | 1200 | 1800 | 3000 |

| Over in the cylinder | Mm | Ф 600 × 1500 | Ф 800 × 1500 | Ф 800 × 2000 | Ф 1000 × 2000 | Ф 1000 × 2600 | Ф 1200 × 2600 | Ф 1400 × 3400 |

| Stirring revolution | Rpm | 5-25 | 5-12 | 5 | ||||

| Power | Kw | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 22 |

| Design pressure of jacket | Mpa | ≤ 0.3 | ||||||

| Pressure in the cylinder | MPa | -0.09- -0.096 | ||||||

Note:

The evaporated amount of water its related to the characteristics of raw materials and the drying temperature. With renew products unceasingly, the related parameter will be exchanged, it does not announce in advance, pardon!