Low-Temperature Spray Dryer

Researchers are all along beset by the problem of rapid drying of heat-sensitive materials, as common vacuum drying and spry drying will result in serious damage to biological activity or structure of materials, long time of freeze drying, low energy efficiency, and regrinding of massive material after drying. By long-term practice and study, researchers have realized that low-temperature spray drying can effectively solve the drying problem of heat-sensitive materials, and have elaborately developed the new type low-temperature spray dryer, which is combined with advantages of laboratory spray dryer and vacuum dryer, and available for rapid drying (1 second) of materials under an inlet air temperature around 80℃. It has provided an easy and safe method for drying of heat-sensitive materials, and is known as the dedicated equipment for drying of emulsion, suspension, paste, solution and other liquids. It is particularly suitable for drying of polymer, resin, fuel, pigment, ceramics, glass, rust remover, insecticide, carbohydrate, dairy product, detergent, surfactant, fertilizer, organic and inorganic compounds.

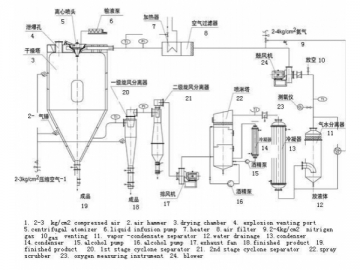

Operating Principle:

Air enters through the filter and heater into the air distributor at the top of dryer, and hot air is spirally and evenly led into the dryer. The feed liquid in the tank is pumped through the filter into the centrifugal atomizer at the top of dryer for spraying into small vaporific droplets, which, in contact with hot air in co-current flow, are rapidly evaporated and dried into the finished product in a very short time. The finished product is discharged from the bottom of drying tower and cyclone separator, and exhaust gas vented by the fan.

Technical Characteristics:

(1) The whole experimental process of spray drying is completed in a vacuum environment; the drying temperature of material is greatly reduced, and the spray drying problem of thermo-sensitive materials solved.

(2) Operation by large color touch screen: Heating temperature is under PID control, and the feed rate of peristaltic pump can be regulated at any time.

(3) Imported Oil-Free Air Compressor is installed, the sprayed particles have a normal distribution of size and good liquidity, and the operating noise is very low in compliance with the national noise standard for laboratory.

(4) The product has good dispersibility, liquidity and solubility, and the size, density and moisture content can be regulated in certain ranges.

(5) To meet the requirements for adjustment of various parameters in the scope of experiment, the real-time PID control technology is adopted for control of drying temperature in the whole range at an accuracy of ±1℃.

(6) Feed rate can be regulated by the peristaltic pump; the rated handling capacity is 800 mL/h.

Applications:

Chemicals: Catalyst, resin, synthetic detergent, grease, ammonium sulfate, dye, dye intermediate, silicon dioxide, graphite and ammonium phosphate etc.

Food: Amino acid and analogues, condiments, protein, starch, dairy products, coffee extract, fish meal and meat extract etc.

Medicine: Chinese patent medicine, pesticide, antibiotics and dissolved medicines etc.

Ceramics: Magnesium oxide, porcelain clay, metalic oxides and dolomite etc.

Spray granulation: various kinds of fertilizer, aluminum oxide, ceramic powder, pharmaceuticals, extra hard steel, chemical fertilizer, granular detergent and Chinese patent medicine.

Spray cooling-granulation: amino fatty acid, paraffin, triglycerides, tallow, etc..

Spray crystallization, spray concentration, spray reaction and so on are often used.