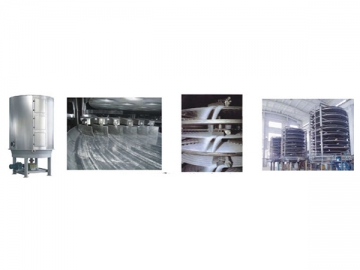

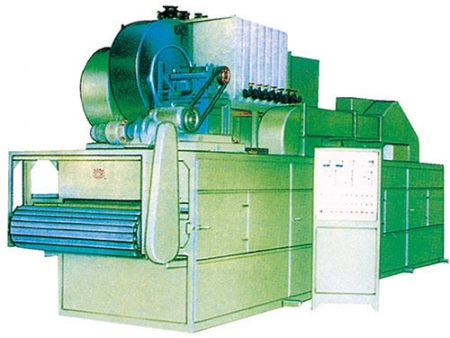

Continuous Vacuum Belt Dryer (for Liquid)

Description:

Low temperature vacuum liquid multi-layer dryer is a kind of vacuum drying equipment with continuous feeding device and continuous discharging device, which is applicable to the drying of maltose, sucrose, sugar beet sugar, and other kinds of sugar. The machine solves the big problem for Chinese traditional medicine extract with high concentration and high viscosity through alcohol-extraction.

Shortcomings of Traditional Dryer:

Low temperature continuous vacuum dryer is a new concept of high efficiency and energy saving type drying equipment, which has been successfully developed after repeated comparison of the advantages and disadvantages of conventional spray drying and freeze drying.

In drying course for the products such as in traditional Chinese medicine, western medicine, chemical, food, health care products and other industries, spray drying is beneficial to cost, but there is a great defect in the solubility of the product, the original favor and the shape of the powder, and it can do nothing to the products which has a slightly higher viscosity and the heat sensitive products. Conventional freeze drying can get product with an excellent solubility and high quality, but the yield is too low, and the cost is too high.

Features and advantages of low temperature continuous vacuum dryer:

Low-temperature continuous vacuum dryer process indexes just somewhere between the two devices between, both to ensure that there is no change to the material’s original natures, such as heat sensitivity, solubility, original flavor, fragrance and etc. Besides the shape-formation is good, which can realize that the dried products is porous and loose inside, maintaining the original material natures and a good appearance. Due to it is low temperature and vacuum drying, so it can meet the processing requirements of the most sensitive material, and is widely used in biological, pharmaceutical, food, chemical industry. The equipment has the features such as energy saving, low temperature, high productivity, stable performance, safe and reliable.

The low temperature continuous vacuum dryer breaks through the technically difficult problem of the continuous feeding and discharging under the vacuum state, which turns the static drying into dynamic drying successfully, realizing continuous feeding, discharging and shaping through crushing in vacuum state and avoiding two times of pollution and the oxidation-reduction of the oxidizable materials. The entire production process achieves a fully closed production, which is pipelined, automatic, continuous, thus the yield of dry powder reaches more than 99%, and the solvent recovery rate is more than 90%.Because the man-machine interface operation management system has been realized, the output of the dry product is greatly improved, and the production cost is reduced. At the same time, whether the equipment or the entire production process is in strict compliance with national GMP and environmental protection requirements, achieving the the "high efficiency, energy saving, green, environmental protection" in the national "12th Five-Year-Plan" .

Low temperature continuous vacuum dryer is especially suitable for the drying of the material with high viscosity, high fat, high sugar, which is the too difficult to be solved for spray dryer and vacuum drying oven. And it can keep the stability and consistency of product batch.

Technical Features:

1. In the vacuum state to achieve continuous feeding and discharging, feeding amount can be set freely according to needs.

2.The heating system using steam, hot water and electrical heating transferred to thermal oil heating and other forms.

3. The drying temperature can be adjusted from 20℃ to 150℃ ,and in 20 minutes to 90 minutes it starts to discharge material continuously until the completion of the batch production.

4. The track is made of Teflon material, stable operation, reliable and uniform heating area. Track speed can be adjusted, and the number of layers of 2 to 10 layers, determined according to the user's production requirements.

5. Using a variety of material-distribution device, which can adapt to the drying for the liquid, extract, powder and granular material etc..

6. Equipped with automatic grinding system under vacuum conditions, mesh number for dry particle can be chosen according to the requirements of the user.

7. With CIP cleaning system, automatic cleaning, it is fast and convenient.

8. Selection of high quality vacuum unit and carefully designed and combined, with continuous high capacity of pumping rate and stable vacuum.

9. Low energy consumption, no three wastes, low noise.

10. Fully comply with the requirements of GMP certification.

Major Advantages:

A full set of process is automatic, pipelined, continuous, programmed.

Complete the drying process in vacuum under low temperature, no nature change to heat sensitive materials, no chance of contamination.

Suitable for the drying of all kinds of highly difficult materials. High viscosity materials do not stick to the belt(Teflon PTFE for the conveyance belt), and shape of crystal material is not damaged aft being dried.

Material dryness (moisture content) can be adjusted.

Energy consumption is only 1/3 of a centrifugal spray dryer for the same output, and 1/6 of freeze dryer.

The moisture content of the product can be optimized and combined with the main parameters such as temperature, vacuum degree and speed of the drying process, so that the work utilization rate of equipment can achieve the best economic benefit.

Using PLC touch screen automatic programming operation and control system, and configurated with continuous protection device. High degree of automation can greatly reduce the cost of labor force operation.

This machine is reasonable in design, compact in structure, convenient in installation and commissioning, and is suitable for installation under most working conditions.

Suitable for large batch, continuous, automatic operation.

| Model | Diameter mm | Length mm | Height mm | Heating area m2 | Drying Temp. ℃ | Feed moisture level % | Moisture level in dry material % | Heating medium | Water evaporation kg/h | Power of main set kw |

| ZD4-2 | 1000 | 5060 | 2100 | 4 | 20-120 | 20-80 | 0.2-5 | Steam or hot oil | 3-4 | 4.00 |

| ZD20-4 | 1400 | 8850 | 2650 | 20 | 15-18 | 8.00 | ||||

| ZD30-4 | 1700 | 9800 | 2700 | 30 | 20-28 | 10.00 | ||||

| ZD60-6 | 2200 | 10800 | 3550 | 60 | 45-55 | 14.00 | ||||

| ZD80-5 | 2200 | 16100 | 3550 | 80 | 65-75 | 14.50 | ||||

| ZD100-6 | 2200 | 16100 | 3550 | 100 | 80-90 | 15.50 | ||||

| ZD120-7 | 2200 | 16100 | 3550 | 120 | 100-110 | 16.50 | ||||

| ZD160-8 | 2800 | 17300 | 4100 | 160 | 120-140 | 18.50 | ||||

| ZD186-10 | 2800 | 17300 | 4150 | 186 | 150-170 | 25.50 | ||||

| ZD200-10 | 2800 | 17300 | 4150 | 200 | 160-180 | 25.50 |

Notes:

If the solvent is organic solvent (ethanol, acetone, methanol, etc.), the evaporation of equipment will be greatly improved.

The evaporation rate is closely related to the temperature of the drying process.

Scope of Applications:

Applicable to the drying for various sugars like maltose, malted milk, cane sugar, beet sugar, dextrine, oatmeal, corn steep liquor, rice flour, honey, coffee and various materials containing high sugar content. The machine solves the big problem for Chinese traditional medicine extract with high concentration and high viscosity through alcohol-extraction. This machine is also applicable to low temperature drying for various paste-like liquid raw materials such as Chinese traditional medicine and Western medicines, polysaccharide medicine, biological engineering, chemical raw materials, food additives and etc., especially for products with high viscosity, or easy to agglomerate, thermoplastic, heat sensitive.

| Item | Vacuum low temperature belt dryer | Freeze dryer | Vacuum drying oven | Spray dryer |

| Drying temperature | Low , Medium temperature | low temperature | Medium ,high temperature | High temperature |

| Drying time | 30-60 minutes | 20-35 hours | 10-20 hours | fast |

| Product solubility | excellent | excellent | averagely | averagely |

| Product quality | excellent | excellent | averagely | averagely |

| Material storage | good | good | averagely | averagely |

| Operation cost | low | high | medium | high |

| Plant investment | medium | high | low | low |

| Application scope | widely | averagely | widely | narrowly |

| Continuous production | yes | no | no | yes |