Puff Pastry Production Line

Here at Jiatong, as a leading bakery machinery manufacturer in China, we are proud to offer a high quality, efficient and low cost production line for pastry products. Our puff pastry production line is mainly used for making all kinds of pastries including puff pastries, pies, sweetheart cakes, mung bean pastries, French breads, hamburgers, etc.

Production Line Introduction

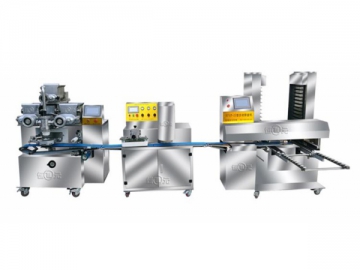

The pastry machinery consists of multi-functional dough forming machine, split-type stuff filling machine and split-type decorating equipment.

Finished stuffed pastries

Finished stuffed pastries1. Via a large sheeting roller, the dough can be pressed into thinner dough bands. Further, the dough bands will be gradually thinned through a group of rollers. This can produce more glossy dough bands with more stable quality. Finally, the dough bands will be rolled into required specifications by a roller that can adjust their thickness.

2. Built in photoelectric control system can automatically adjust the speed of rollers, ensuring high automation level.

3. The pastry production line comes in three roller widths that can be selected according to product specifications, or customized to customers' special needs.

4. Used with other peripheral equipment, the bakery equipment can produce diversity pastry products.

Puff Pastry Production Line Features

1. Compression ratio of rollers to dough is 6:1 (Depending on dough characteristic).

2. Fully automatic flour duster system is suitable for all kinds of dough.

3. In the food processing machine, all accessories that can touch the food are made from food grade materials.

4. It will not break the dough band tissue and not heat it, maintaining traditional flavor.

- Integrated PLC Control

- Rollers made from Japanese materials

- Decorating equipment

- Stuffing hopper

This dough molder is mainly used for the production of pastries. It mainly comprises three roller systems:

1) First Roller System: Roll the dough into dough band;

2) Second Roller System: 12 small rollers continuously press the dough band, making it more thinner and glossy;

3) Third Roller System: Adjust and form the dough band into desired specifications. Molded dough bands will be folded into long strips.

Speeds of all rollers are controlled by variable frequency motor, ensuring stable and reliable performance. PLC programmable control system ensures synchronous control. All operations can be easily completed via the touch screen.

Features

1. Three roller systems in the puff pastry production line are specially designed to realize manual rolling effect, so as to make the dough band much tougher. They can ideally meet the requirements for production of breads and pastries.

2. Stuffing machine employs dough auger scraper feeder. It can feed both hard and soft stuffing.

3. Decorating equipment is provided with nine decorating blades, ensuring high uniformity.

| Capacity | Power | Voltage | Weight | Dimensions (L×W×H) |

| 20-80pcs/min | 3.5kw | 380V | 750kg | 3000×735×1450mm |

The machine applies horizontal feeding method. Three auger feeders in double layer can uniformly deliver the stuff in the hopper. It is perfect for filling various types of stuffs such as meat stuffing, sweetened bean paste stuffing, mixed nuts stuffing, etc. Discharging port size can be customized.

Technical Parameters| Capacity | Power | Voltage | Weight | Dimensions (L×W×H) |

| 20-80pcs/min | 0.75kw | 380V | 180kg | 800×600×1000mm |

Cutter of the decorating equipment in our puff pastry production line is composed of 9 blades which provide high precision and are all made from food grade materials. Due to an automatic lubricating unit, cutter wear can be considerably reduced. Conveyor belt comes with intermittent and continuous running functions.

Technical Parameters| Capacity | Power | Voltage | Weight | Dimensions (L×W×H) |

| 20-80pcs/min | 1.5kw | 380V | 200kg | 1300×900×900mm |

- Running puff pastry production line

- Decorated pastries conveying

- Press

- Rolled dough band

- Encrusting

- Dough feeding port

Stuffed pastries

Stuffed pastries