3D Printing

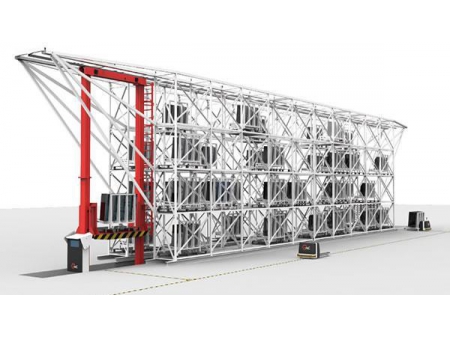

Borui Model possesses SLA and SLS devices to finish the production of our customers' prototypes in a timely manner.

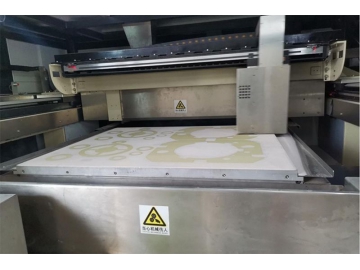

The SLA (Stereo lithography Apparatus) process is also known as optical fabrication, stereolithography and three-dimensional printing. In the SLA process, the liquid tank is filled with liquid of photosensitive resin. The laser beam is controlled by the computer to draw the desired cross-sectional shape on the photosensitive resin in the liquid tank. The track drew by the laser beam is solidified. Next, the platform is lowered at one-layer-height and recoat the solidified resin layer with resin. Conduct the scanning process again at this layer so that the newly solidified layer strongly adhered to the previous layer. This process is repeated until the production of the desired part is completed. A 3D model is created from this process.

Borui Model uses second generation 14120 photosensitive resin from SOMOS, company from United States. Products made from the resin has high toughness (which is closed to ABS), high precision, deviation controlled at ±0.05mm. Besides, complicated structure and curve surface do not limit the production of the products with the use of the resin.

Advantage: High accuracy, strong and tough parts, able to manufacture hollow parts with extremely complicated shape, good flexibility of the manufactured model, allow dismantling at will, is an ideal way to manufacture the model indirectly.

Disadvantage: Require support during manufacturing, contracted resin reduces accuracy

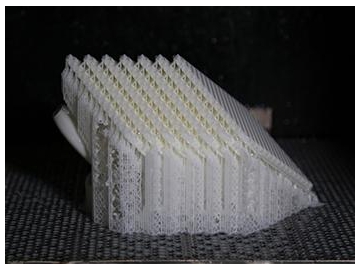

The SLS (Selective Laser Sintering) process is commonly used with powders made up of metal, ceramic, ABS plastic and so on to create the end-product. In the SLS process, powder is scattered on the platform and the laser beam is controlled by the computer to draw out the desired shape on the powder layer. (The hollow region of the part is not sintered and thus it remains in powder form). The sintered region is then solidified and becomes solid part of the product. The process is repeated for many layers and the adjacent layers strongly sintered together. At the end of the process, remove the powder residue and the sintered part is collected. The specialty of SLS process is that it has a wide range of application, not only manufacturing plastic part but parts from ceramic, metal, wax and so on as well. It has high precision in creating the prototypes and the prototypes are tough which make them ideal for performance testing and installation simulations.